Implementing lean management in production companies: Basics, benefits and examples

Lean management is a company-wide strategy for process optimization by reducing waste and continuously improving processes. Unlike traditional business management, lean management maximizes company profits purely by minimizing costs.

In contrast to classic lean manufacturing (also known as lean production), which focuses mainly on production, lean management extends to the entire company, including administration, logistics and service.

The core of lean management is waste reduction (muda). Waste includes all activities that consume resources but do not create any direct added value for the customer. These non-value-adding activities can take the form of overproduction, waiting times, unnecessary transportation or over-processing.

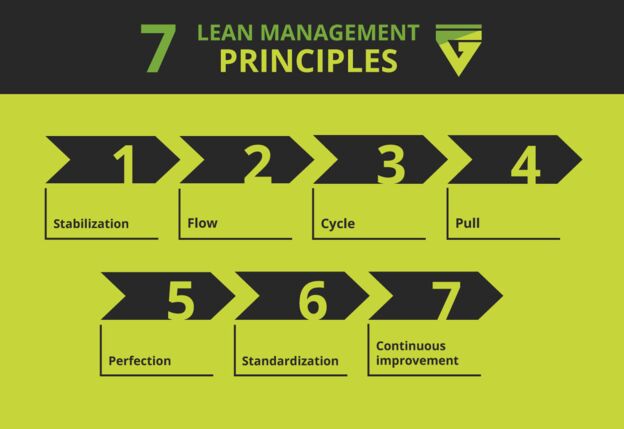

The principles of lean management form the basis for its methodical implementation. These include the stabilization of processes, the establishment of a continuous flow, the timing of production according to customer demand, the pull principle, in which production is only carried out on demand, and perfection, i.e. continuous optimization. Standards play a central role here, as they ensure repeatable and efficient processes. The concept of continuous improvement (Kaizen) ensures long-term success by promoting the ongoing optimization of all processes.

Lean management can be applied in many ways and has established itself in manufacturing and assembly in particular. In manufacturing, lean principles manifest themselves in automation and precise process control. Overall equipment effectiveness (OEE) and preventive maintenance (TPM) play a decisive role in maximizing the availability and efficiency of systems. New technologies such as Industry 4.0 are also being used in combination with lean principles to drive forward the digitalization of production.

In this article, as an experienced and successful production company, we introduce the basics, principles and methods of lean management and show examples from practice.

What is lean management?

Lean management is a company-wide strategy for optimizing processes by reducing waste and increasing efficiency.

The focus is on creating added value for the customer while minimizing the use of resources.

Originally developed from lean production, a production system from Toyota, the principles of lean are now applied in various areas of the company, such as assembly and production.

The central objectives of lean management include improving quality, shortening delivery times and reducing costs.

A practical example of the application of lean management in production is the optimisation of liquid filling processes, a key topic in GREIF-VELOX's system development.

Liquid filling systems from GREIF-VELOX are designed to efficiently fill different types of containers such as canisters, drums and IBCs with a wide range of liquids - from aqueous to highly viscous.

Bottom-bottom, top-bottom and bottom-bottom filling not only ensures filling accuracy, but also standardises and optimises the process flow. This reduces unnecessary work steps and ensures that production time and the use of resources are minimised, which means nothing other than minimising waste.

What is the difference to Lean Manufacturing System (Lean Production)?

Lean Management and the Lean Manufacturing System (also known as Lean Production) both originate from the Toyota Production System, but are different in their scope of application.

Lean production focuses mainly on waste-free processes in production. The aim is to organize processes according to the principles of stabilization, flow, cycle, pull and perfection in order to achieve high product quality, short delivery times and low costs.

Lean management, on the other hand, is a holistic corporate strategy that goes beyond production. It encompasses not only production, but also areas such as administration, logistics and service.

The main difference is therefore that lean management is more strategically oriented, integrating the corporate culture and continuous improvement across all company processes. Lean production, on the other hand, remains focused on the optimal design of production processes.

What is the conceptual approach of lean management?

Lean management aims to eliminate waste in all company processes and maximize efficiency, which distinguishes it from the approach taken in traditional business administration.

In lean management, customer needs are consistently placed at the center of attention. Waste (Japanese: muda) refers to all activities that do not create direct added value for the customer but consume resources.

The concept of waste

In lean management, waste refers to any activity that consumes resources but does not create direct added value for the customer.

These types of waste are defined as the seven classic types of waste: Overproduction, waiting times, transportation, unnecessary movements, defective products, over-processing and inventory.

The aim of lean is to consistently reduce or eliminate these non-value-adding activities in order to optimize the use of resources and make processes more efficient.

The customer concept

Lean management focuses on the customer (Kansei), whose needs form the basis of all activities.

Creating value means doing exactly what the customer considers valuable. This approach requires a deep understanding of customer requirements and flexible production geared to demand.

Waste that does not directly serve customer demand must therefore be avoided. Focusing on the customer not only increases efficiency, but also ensures customer satisfaction in the long term.

How does the concept of lean management differ from traditional business management?

Lean management and business administration pursue similar goals, but in different ways. While traditional business administration aims to maximize profits through higher prices or higher sales volumes, lean focuses on reducing costs by minimizing waste.

The price and quantity are determined by the market, so the focus is on reducing costs through more efficient processes. This approach makes it possible to sustainably increase profits despite unchanged prices and quantities.

In order to achieve the ultimate lean goal of eliminating waste in companies and thus increasing the efficiency of the value chain, lean management follows various lean principles when implemented in a company. These are implemented in the company one after the other.

Lean management is introduced into companies according to the following seven principles:

1. Stabilization: processes should run stably and smoothly in order to avoid fluctuations and inefficient processes

2. Flow: materials and information should flow continuously and without interruption through the processes

3. Cycle: Production is adjusted to actual customer demand in order to avoid overproduction

4. Pull: Products and services are only produced on demand, i.e. as required

5. Perfection: Continuous improvement (Kaizen) is the overriding goal in order to continuously optimize processes

6. Standardization: A high degree of process standardization forms the basis for consistent quality and efficiency

7. Continuous improvement: Kaizen ensures that every step in the company is regularly scrutinized and improved

Stabilization

One of the central challenges in lean management is the stabilization of processes, as only stable processes can be efficient and waste-free in the long term. Instabilities caused by fluctuations, failures or inefficient process steps lead to higher costs, longer throughput times and increased waste.

These are the three main factors that affect the stability of a process:

1. Waste (muda): Waste causes inefficiencies and hinders the smooth running of processes. The classic types of muda include overproduction, unnecessary transportation routes and waiting times. Avoiding waste is therefore a key objective in stabilization.

2. Inflexibility: Inflexibility occurs when a system is unable to adapt quickly to changes in demand or unforeseen disruptions. This is often seen in rigid production systems that are difficult to change or in systems that are only designed for high production volumes and become inefficient at lower utilization rates. To ensure stability, companies need to create flexible working models and production facilities that remain efficient even when requirements change.

3. Variability: Variability is caused by fluctuations in the process sequences, such as different processing times, manual interventions or uneven material supply.Deviations from the standard lead to delays and impair the production flow.Variability can be reduced by consistently adhering to standards and continuously improving them. It is important that the processes are designed in such a way that they work reliably even in the event of unforeseen events.

Flow

The principle of flow in lean management aims to ensure that products, information and materials flow continuously and without interruption throughout the entire production process. This continuous flow minimizes throughput times, reduces inventories and eliminates unnecessary waiting times.

One example of the implementation of lean management principles is the integration of full-line filling systems in the area of liquid filling. Liquid filling systems from GREIF-VELOX combine several steps of a production process in an integrated, automated solution. This includes the provision of the containers, precise filling, automatic opening and secure capping as well as the subsequent storage and transport protection of the filled products.

This seamless integration of the process steps enables the lean principle of continuous flow to be realised: Production interruptions, such as the manual transfer of containers or time-consuming quality checks, are avoided through automation.

In addition, the principle of waste reduction is applied, as the systems minimise both material losses and unnecessary working times through real-time control and precise dosing. Translated with DeepL.com (free version)

Production processes must be stable and standardized to ensure an optimal flow, as even minor deviations lead to interruptions. Reducing batch sizes is particularly important here.

Another central factor for the flow is the layout of production. Minimizing transport routes plays a key role here. A U-shaped layout, as is often used in lean factories, reduces transportation routes by limiting the material flow to the shortest possible distances: Materials are provided specifically where they are immediately needed, which makes the entire process more efficient. Such a layout also provides a better overview of the production status and increases the transparency of processes.

Cycle

The cycle principle in lean management refers to the rhythm in which products are manufactured in order to meet customer demand. The customer cycle (cycle time) specifies the intervals at which a product should leave production.

By precisely calculating the customer cycle time, production can be organized in a stable and predictable manner. This process ensures that production does not take place faster or slower than necessary, thus avoiding waiting times, overproduction and unnecessary stock. An optimal cycle enables an even utilization of the workstations and a continuous material supply.

Pull

The pull principle is a central component of lean management, which is designed to ensure that production and material flow are based exclusively on actual customer demand.

In contrast to conventional push systems, which produce to stock, the pull principle only produces when there is an order or demand. This avoids overproduction and unnecessary stock.

By implementing the pull principle, companies can drastically reduce throughput times and inventories while ensuring that they can react flexibly to fluctuations in demand. Transparency in the production process is also increased, as each production step is based on actual demand.

Perfection

In lean management, the principle of perfection strives to continuously improve all processes in order to deliver flawless products and services.

Perfection means that no step in the production process creates unnecessary waste and that no errors are passed on to subsequent process steps. The aim is not to find errors through subsequent quality checks, but to produce zero-defect products through a perfect process right from the start.

Standardization

In lean management, standardization plays a key role in creating stable and repeatable processes.

Standards define the most efficient and safest way to carry out an activity. They form the basis for high process reliability and consistent quality. Standards are not regarded as unchangeable norms, but as dynamic specifications that can be continuously improved.

The standard in a process is always the best, currently known way to achieve the desired performance and serves as the basis for training and continuous improvement (Kaizen).

A key goal of standardization is to make processes independent of people so that results are achieved consistently and reliably, regardless of who is doing the work. This reduces errors and fluctuations that could occur if working methods vary. Standardized processes also improve interfaces with other departments and enable seamless collaboration between different work areas.

Furthermore, standardization serves as a basis for problem solving. By having a clearly defined standard, deviations can be easily identified and rectified in a targeted manner. Without these clear guidelines, it is more difficult to identify sources of error and initiate improvement measures.

One example of the benefits of standards is shift changes: if work processes are not clearly described, this leads to delays and potential errors that can be avoided through standardized handover processes.

Standards are applied in various areas, such as work processes, machine settings and material provision. These standards are not just documentation, but are regularly taught in training sessions and monitored in practice to ensure compliance. In this way, companies can not only ensure quality, but also continuously increase efficiency and safety in production.

Continuous improvement

In lean management, continuous improvement (CIP) forms the foundation for long-term success. CIP is based on the Japanese philosophy of Kaizen, which means “change for the better”.

The aim is to continuously optimize processes in small steps instead of relying on radical changes. This requires daily commitment from employees, as they themselves actively contribute to improving their work processes.

An important difference between CIP and other optimization approaches is that CIP aims to make improvements in the most resource-efficient way possible. Each improvement should lead to a more efficient use of manpower, time or materials without causing additional effort. Kaizen is not understood as a mere suggestion scheme, but as an integral part of the daily work philosophy, in which employees are proactively involved in improving their work processes.

A distinction is made between two forms of CIP: point kaizen and system kaizen. Point kaizen refers to improvements at individual process stations and focuses on specific problems, such as reducing waste at a workplace.

System Kaizen, on the other hand, concerns the holistic optimization of the entire value chain and is usually carried out by experts. Both approaches are necessary in order to exploit the full potential of continuous improvement.

Each lean management principle is put into practice through the application of specific lean methods. There are different methods for each of the seven lean principles mentioned. These are supplemented by lean methods for value stream optimization.

The eight lean management methods are as follows:

1. Lean methods for stable processes (stabilization)

2. Lean methods for flowing lean production (flow)

3. Lean methods for common-mode processes (cycle)

4. Lean methods to switch to pull production (pull)

5. Lean methods for optimal value streams and material flows

6. Lean methods to achieve flawless production (perfection)

7. Lean methods to stabilize perfect production (standardization)

8. Lean methods for continuous improvement

Lean methods for stable processes (stabilization)

Stabilizing processes is crucial to ensure consistent efficiency and quality. Unstable processes lead to fluctuations, delays and additional costs. To avoid this, the following five methods are used in lean management:

1. Leveling and smoothing (Heijunka): This method ensures that production is evenly utilized, even when customer demand fluctuates. Leveling distributes the production volume evenly over the working day, avoiding capacity fluctuations and reducing bottlenecks. The aim is to minimize fluctuations and unnecessary waiting times.

2. Standardization: Standardized processes and clear work instructions create stability. Standard operating procedures (SOPs) ensure that all work steps are carried out uniformly, regardless of who carries them out. This reduces errors and variability in the processes.

3. 5S method: This method of workplace organization (sorting, setting, cleaning, standardizing, self-discipline) helps to create a clean and well-organized workplace. This avoids unnecessary searching and waiting times and makes the entire process more stable and efficient.

4. Total Productive Maintenance (TPM): Regular and predictive maintenance of the machines ensures that the production facilities remain in optimum condition and unplanned downtime is minimized. TPM actively involves employees in maintenance and thus ensures greater process reliability.

5. Problem-solving cycle (PDCA): The Plan-Do-Check-Act cycle helps to create stability by focusing on continuous improvement. Problems are identified in small steps, solutions are implemented and then tested for their effectiveness

Lean methods for flowing lean production (flow)

In lean management, materials, information and products are continuously moved through the entire production process without interruption to ensure smooth production. This minimizes unnecessary waiting times, reduces inventories and ensures maximum efficiency.

Four methods are used to implement the flow principle:

1. One-Piece-Flow: Each part is fed through the production process individually instead of being produced in large batches. The advantage lies in the early detection of errors and the fact that errors are rectified more quickly. This significantly reduces throughput time and minimizes stock levels. This method is used in particular where a rapid response to customer requirements is needed.

2. Optimization of the layout: A flow-oriented layout reduces transport routes and makes the material flow transparent. Processes are arranged in such a way that products move from one station to the next without detours and delays. A popular layout form is the U-shaped arrangement, which enables short distances and efficient material movements.

3. Batch size reduction: Large batch sizes often lead to long waiting times and higher inventories. To improve the flow, the batch size is reduced as much as possible, ideally to a one-piece flow. This makes it possible to react more flexibly to fluctuations in demand and avoid unnecessary warehousing.

4. Cycle time and clocking: For the flow to function smoothly, the individual process steps must be coordinated with each other. The cycle time of each station is adjusted so that it corresponds to the overall cycle of the production system, thus avoiding bottlenecks. This even synchronization is crucial for continuous production.

Lean methods for synchronized processes (cycle)

The cycle principle in lean management is based on customer demand and determines how quickly a product must be manufactured in order to efficiently meet market requirements. The cycle time is determined by the available production time and the customer order quantity.

Four methods are used to ensure that production runs evenly in cycle:

1. Customer cycle calculation: Calculating the cycle time is the first step. The available working time is divided by the number of units ordered by the customer. This creates a clear target for production in order to avoid overproduction and bottlenecks.

2. Balancing: Balancing distributes the work steps along the production line so that each step is completed exactly within the cycle time. The even distribution of tasks to the individual workstations ensures that neither waiting times nor overloads occur. This approach requires precise analysis and adjustment of the workflows.

3. Bottleneck management: As every process is only as fast as its slowest step (bottleneck), the identification and elimination of bottlenecks is crucial. Methods such as bottleneck analysis and continuous monitoring of production processes help to identify potential weak points and optimize them in a targeted manner.

4. Visualization of the cycling process: A visual representation of the clocking process, for example through Andon boards, enables real-time monitoring of production. This improves transparency and ensures rapid intervention in the event of deviations from the cycle.

Lean methods for switching to pull production (Pull)

Pull production ensures that only what the customer actually needs is produced. This reduces inventories and avoids overproduction. The pull principle is based on customer demand, which controls the production process.

Three methods ensure the introduction of an effective pull system:

1. Kanban: Kanban cards or other visual signals control replenishment and trigger the production or transportation of materials. As soon as material is used up at a station, a Kanban card signals the need for replenishment. This ensures that production only takes place according to actual demand and that no unnecessary stocks are created.

2. Just-in-time (JIT): This method ensures that materials and components are delivered exactly in the quantity and at the time they are needed. Just-in-time reduces storage costs and ensures a high degree of flexibility by adapting production to actual demand. In contrast to the push principle, where production is made to stock, JIT delivers exactly what is needed.

3. Pacemaker process: The pacemaker is the point in the process chain at which customer demand is fed into production. This process controls the pace of the entire production process and ensures that production follows the pull principle. The processes upstream of the pacemaker work according to the pull principle, while the downstream processes often work according to the first-in-first-out (FIFO) principle.

Lean methods for optimal value streams and material flows

A central task in lean management is the optimization of value streams and material flows. The value stream comprises all activities, both value-adding and non-value-adding, that are necessary to manufacture a product or provide a service. Targeted analysis and optimization of value streams reduces waste and makes processes more efficient.

Lean methods for optimizing value streams and material flows are:

1. Value stream mapping: Value stream mapping is a central method for visualizing and analyzing process chains. It shows the current state of a process (actual state) and identifies non-value-adding activities that are considered wasteful. By creating a target value stream, a future target picture is drawn that forms the basis for optimization. The target value stream helps to create action plans and introduce targeted improvements in order to improve material and information flows.

2. Design of the material flow: Ideally, the material flow is supported by a flow-oriented layout in which the materials arrive directly at the required work stations without detours and delays. This avoids unnecessary transport and minimizes throughput times. In practice, U-shaped layouts are often used, which offer short transport routes and a better overview.

3. Inventory and batch size reduction: High inventories and large batch sizes lead to long throughput times and tie up capital. By reducing batch sizes and introducing just-in-time deliveries, the material flow is streamlined. Smaller batch sizes lead to faster responsiveness to changes in customer demand and thus ensure greater flexibility in production.

4. Continuous flow optimization: After recording the actual value stream, Kaizen flashes are used to uncover weak points and waste in the material flows. These flashes highlight areas that urgently need to be improved, such as unnecessary stock, excessively long transportation routes or bottlenecks. The improvements are implemented in a continuous improvement process in order to sustainably increase the flow rate and efficiency of production.

Lean methods to achieve flawless production (perfection)

Lean management also indirectly means achieving error-free production where no rework or correction is required. This zero-defect production is ensured by four methods that eliminate sources of error and continuously improve the quality of the processes:

1. Jidoka principle: Jidoka combines automation with human control. Machines stop automatically when a fault is detected and the process does not continue until the problem has been resolved. This method prevents defective products from entering the next process step and promotes immediate problem solving.

2. Poka-yoke: Poka-yoke refers to the prevention of defects by technical or procedural measures that make it impossible for defects to occur. Examples of this are devices or mechanisms that ensure that components can only be assembled in the correct orientation. This method makes a decisive contribution to preventing human error and increasing process reliability.

3. Andon system: This visual alarm system immediately signals when a problem occurs in production. Andon boards show in real time where and which errors have occurred and request support. In this way, errors can be responded to quickly and their effects minimized.

4. First pass yield (FTY): This key figure measures the proportion of products that pass through the entire production process without rework. A high FTY value is an indicator of error-free production. FTY is part of continuous quality control and identifies weak points in the process at an early stage.

Lean methods to stabilize perfect production (standardization)

Standardization is a central method in lean management to ensure stable and error-free processes. Clearly defined standards ensure that processes run consistently and efficiently, regardless of who is carrying out the work.

These four methods ensure stable and high-quality production:

1. 5S method: The 5S method (sort, set, clean, standardize, self-discipline) ensures order and cleanliness in the workplace. It ensures that all tools and materials are systematically organized, which not only increases productivity but also minimizes sources of error. A tidy workplace is an essential basis for compliance with standards.

2. Standard operating procedures (SOPs): These detailed work instructions lay out the best known way to perform a task. SOPs create transparency and help to identify deviations and errors at an early stage. They form the basis for training and help to secure knowledge within the company.

3. Visual standards: Visual aids such as andon boards, markers and checklists are used to make work processes transparent. This makes it easier to monitor compliance with standards and enables employees to quickly identify and rectify potential problems.

4. Continuous improvement (Kaizen): Continuous improvement is closely linked to standardization. As soon as a process has been optimized, the new, improved process is standardized in order to safeguard the progress made. This creates a cycle in which improvements are permanently integrated into the way of working.

Lean methods for continuous improvement

Continuous improvement (kaizen) is a central lean principle that calls for processes and workflows to be optimized step by step. Kaizen emphasizes small, incremental changes that take place on an ongoing basis and have a significant long-term impact on efficiency.

There are four methods that systematically implement this improvement process:

1. PDCA cycle (Plan-Do-Check-Act): The PDCA cycle is the basic tool for the structured implementation of improvement projects. This four-stage process begins with the planning of an improvement (Plan), followed by the implementation (Do), the subsequent review of the results (Check) and the standardization of successful measures (Act). This iterative approach ensures that every change is checked for effectiveness and adjusted if necessary.

2. Kaizen workshops: These events focus on solving specific problems in a set period of time. Kaizen teams, consisting of employees from different departments, analyze processes, identify opportunities for improvement and implement immediate solutions. The advantage of such workshops lies in the speed and direct involvement of employees, who can improve their own work processes.

3. Improvement kata: This method supports employee development and problem-solving processes. It involves practising a recurring process that focuses on achieving goals in small steps. The kata relies on a constant review of the current situation, the formulation of hypotheses and their testing. This structured approach encourages employees to think in terms of continuous improvement.

4. Suggestion scheme: Employees are actively involved in the improvement process by submitting their own ideas for optimizing processes. These ideas are evaluated and promising suggestions are tested immediately. This bottom-up principle strengthens employee commitment and increases identification with the improvement goals.

Lean management using the example of the production area manufacturing

In the production area of manufacturing, lean management is implemented through a combination of automation, increased efficiency and precise process control. The following four areas play a central role, particularly with regard to modern production technologies:

1. Automation: In areas with monotonous, repetitive tasks, automation is used to increase productivity and minimize errors caused by human interaction. Automation of production is particularly suitable for low product variance and stable production volumes. However, it also poses challenges: Machines need to be regularly maintained and repaired in the event of malfunctions, for example, which reduces availability. In addition, set-up requires specialized knowledge.

2. Overall equipment effectiveness (OEE): Overall equipment effectiveness is an important key figure for measuring the efficiency of machines and systems. It records the actual output in comparison to the maximum possible output and reveals losses in the areas of availability, performance and quality. By consistently optimizing the OEE, unproductive times are identified and reduced, resulting in better utilization of the production facilities.

3. Total productive maintenance (TPM): TPM focuses on preventive maintenance of machines in order to minimize downtimes and extend the service life of the systems. It actively integrates employees into the maintenance process in order to identify and rectify faults before they become major problems. This improves the availability and efficiency of production facilities.

4. Industry 4.0: The digitalization of production brings additional opportunities for optimization. Industry 4.0 links machines, systems and processes through the use of technologies such as sensors, big data and artificial intelligence. This allows real-time data to be used to monitor and improve production. A key success factor is that lean principles such as waste reduction serve as the basis for the introduction of Industry 4.0. This is the only way to fully exploit the technological potential.

Once again, an example from liquid filling with GREIF VELOX systems can be used to illustrate this.

Standardisation is achieved through automated capping mechanisms and integrated quality controls. These processes ensure the integrity of the end product and eliminate error-prone manual intervention. For example, the closure is automatically checked for each container, which prevents reworking or potential damage to the product.

Continuous improvement is supported by the use of real-time data and process monitoring. GREIF VELOX liquid filling systems continuously collect and analyse production data, identifying bottlenecks and optimising production in real time.

Lean management using the example of the assembly production area

Lean management is implemented in the assembly production area through a combination of increased efficiency, ergonomic optimization and flexible assembly systems. The focus is on reducing waste and adaptability to fluctuating production volumes.

The four key areas are:

1. Manual activities: Manual activities in assembly must be designed to be waste-free. One example of this is the “one-touch assembly” principle, in which processes are designed in such a way that a product can be assembled with just one movement. This eliminates the need for repeated adjustment or testing. In addition, added value is increased through parallel work processes in which, for example, two assembly activities are carried out simultaneously with both hands. Another principle for path optimization is the “assembly triangle”, in which non-value-adding movements are minimized by efficiently planning the material pick-up and work on the product.

2. Ergonomics: Ergonomics plays a central role in reducing strain and overload on employees. Ergonomic solutions must also be cost-efficient in the sense of lean. In companies that work according to lean principles, standardized work is the basis for ergonomic workstations. This avoids unnecessary movements and ensures the safety of employees. Ergonomic improvements, such as the “Raku-Raku” seat at Toyota, make it possible to work comfortably and efficiently.

3. Flexible employee assembly system (FMS): A flexible employee assembly system, often set up in U-cells, enables consistent productivity, regardless of the number of employees deployed. This enables a flexible response to fluctuations in demand. Such a system reduces investment costs and allows flexible capacity adjustment. Within the U-cells, the material changes from station to station in cycles and the standard circulating stock remains constant. This flexibility makes it possible to adapt to different production quantities without overproduction.

4. Flexible deployment of employees: To ensure the flexibility of assembly, employees must work in different cells. This requires extensive training so that the employees can master the entire process at different stations. At low workloads, one employee must be able to take over all production steps, while at full capacity, several employees share the workload. This minimizes walking distances and increases efficiency.

What variants of lean management are there?

Lean management can be adapted in many areas and can therefore be applied in a variety of ways. The classic approaches include application in production (lean production), but also in administration, development and services. Newer variants have established themselves in areas such as software development (lean development), construction and law. Depending on the context, lean is adapted by focusing on stabilization, flow, pace and pull.

Lean Management and Six Sigma

Lean management and Six Sigma are often combined to increase both efficiency and quality. While Lean focuses on the elimination of waste, Six Sigma aims to reduce process variability through statistical methods. This combination, known as Lean Six Sigma, utilizes the strengths of both approaches: the speed and flexibility of Lean and the data-based precision of Six Sigma to achieve improvements.

Lean management and agile management

Agile management, which is particularly widespread in software development, is based on the principles of lean management. Methods such as Scrum are basically lean approaches that have been adapted to software development. Both systems emphasize continuous improvement, flexibility and customer orientation. While lean pursues the goal of perfecting production processes, agile management focuses on rapid adaptability and iterative development.

Lean Project Management

Lean project management adapts lean principles to project management. It focuses on setting clear objectives, reducing waste in all project phases and closely coordinating project resources with the customer's requirements. Projects are broken down into smaller, manageable work packages in order to be able to react quickly and flexibly to changes. Visualization tools such as Kanban or Obeya help to make progress and challenges transparent.