The VeloFlexLabeler from GREIF-VELOX can be integrated directly into existing production lines and is individually adapted to the specific requirements of your production environment - for maximum efficiency and operational reliability.

High Performance in Container Labeling

Precise Labeling Without Adhesive Failures

VELOFLEXLABELER - HIGH-PRECISION LABELING FOR ALL CONTAINER TYPES

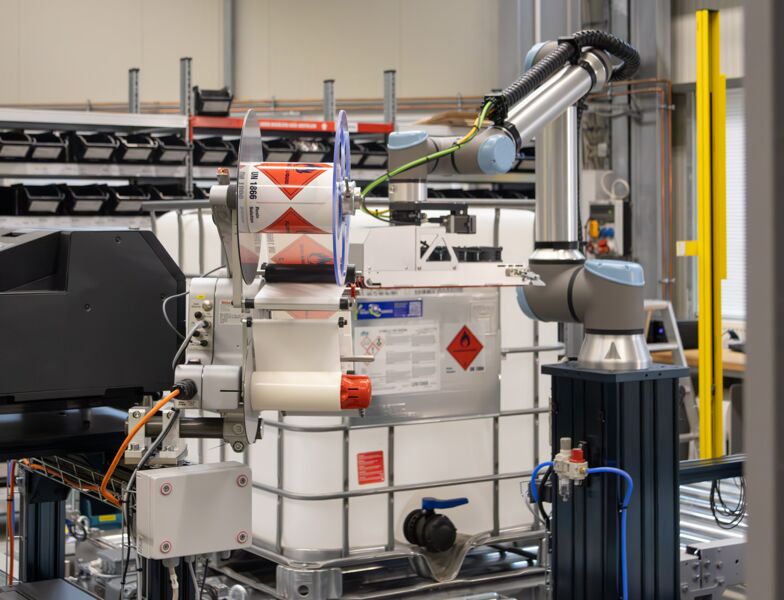

The VeloFlexLabeler by GREIF-VELOX enables precise and reliable labeling of containers such as drums, buckets, and IBC containers. With its redundant printing systems and flexible configuration, it ensures uninterrupted operation even under demanding production requirements.

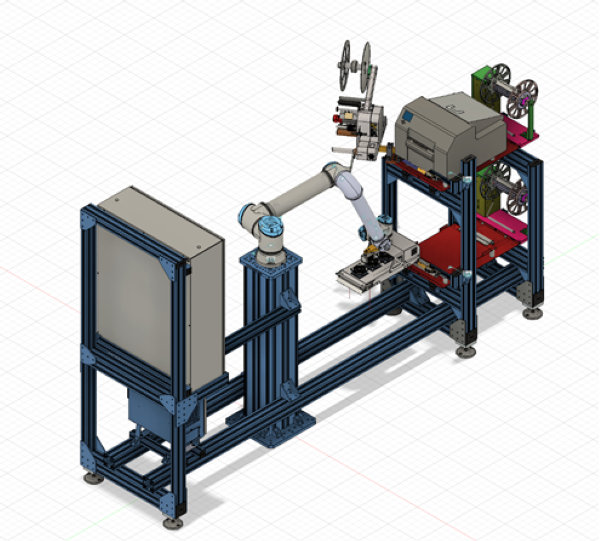

The compact design of the VeloFlexLabeler facilitates integration into existing production lines, while the positioning of labels can be freely adjusted regardless of the size or shape of the containers. This makes the system ideal for industries such as chemicals, food, and logistics.

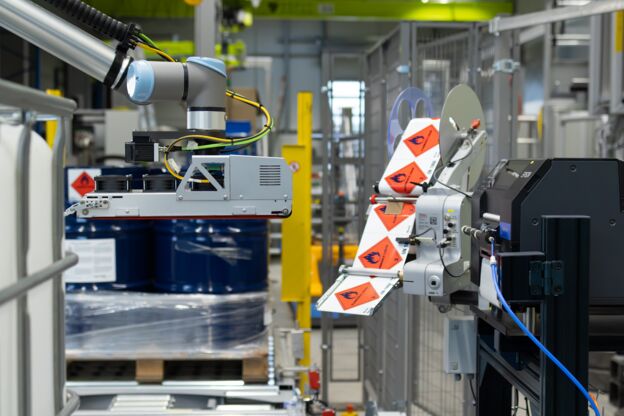

Precise Labeling: Ensures flawless labeling even at high production speeds.

Redundant Printing Systems: Prevent downtime and adhesive failures.

Versatile Application Options: Allows for the application of tamper-evident seals or static warnings.

Maximum Flexibility: Choice of printing and dispensing systems and adaptability to various label sizes.

INTEGRATION OF THE VELOFLEXLABELER INTO EXISTING PRODUCTION ENVIRONMENTS

The VeloFlexLabeler by GREIF-VELOX is specifically designed for seamless integration into existing production lines. It enables efficient, precise, and flexible labeling tailored to the individual requirements of your industry and production processes.

Thanks to its compact design and modular configuration, the VeloFlexLabeler can be used as a standalone system or as part of a full-line setup. This versatility ensures optimal adaptation to various container types and production environments.

Comprehensive System Solutions

The VeloFlexLabeler complements your production chain as a fully integrable element that communicates seamlessly with other systems.

Modular Design

Easy expansion and adaptation to growing production demands.

Scalability

Perfect for container types of all sizes – from small vessels to IBC containers.

Increased Efficiency

Reduction of manual interventions and minimization of labeling error rates.

Single Point of Contact

GREIF-VELOX supports you from planning to implementation – ensuring a smooth project flow.

For over 60 years, GREIF-VELOX has been firmly established in the international markets of the chemical, food and petrochemical industries and is valued by customers and partners for its customized filling and packaging solutions, reliability and innovative strength.

Quote: Managing Director Sebastian Pohl

Became the market leader within just a few years

Our experience is reflected in a large number of projects, such as the increase in packaging efficiency at GoodMillsGroup, where we were able to effectively double production output, and the implementation of our ValvoDetect system at ICL Ladenburg, which led to a significant reduction in complaint and cleaning costs.

These and many other case studies demonstrate our ability to respond to a wide range of industry requirements and provide customized, effective solutions. If you would like to see specific examples of our work or gain a deeper insight into our bespoke installations, please contact the appropriate contact person.