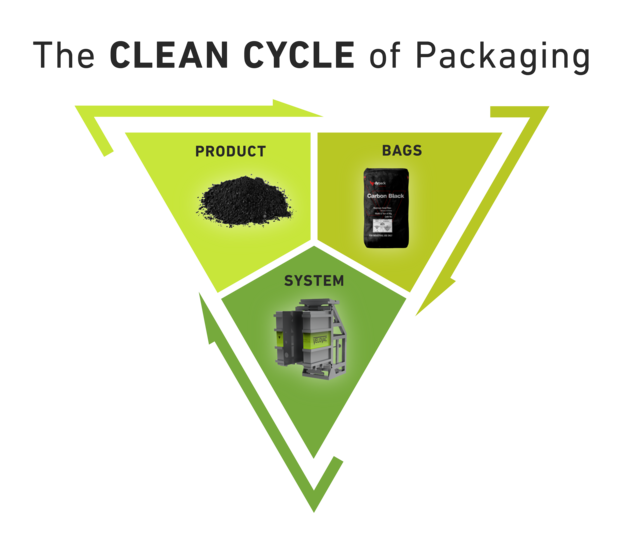

The Clean Cycle of Packaging

With perfectly coordinated components, you set new standards in the clean, compact and efficient packaging of Carbon Black.

Webinar "Clean Cycle of Packaging" mit unserem Marketing Manager Björn Voges auf der Solids-Messe

Webinar "Clean Cycle of Packaging" with our CEO Sebastian Pohl (EN) Powtech Technopharm Virtual Talk

Product:

Carbon Black (industrial carbon black)

The demand for carbon black will increase by around six percent annually in the coming years. The ultra-light powder is used in a variety of applications in various industries, for example:

as a highly effective pigment and dye, e.g. in the printing industry

as a reinforcing agent in rubber and other polymeric materials

as a component of electronic components and batteries due to its electrical conductivity

when absorbing substances from gases or liquids, e.g. in air and water filtration

Due to its properties, Carbon Black is very difficult to sink. The reason for this is the fine particle size, the low bulk density and the high air holding capacity. With conventional bagging processes this leads to:

Dust accumulation in which the entire system environment is contaminated and has to be cleaned in a complex and cost-intensive manner

Danger to employees, because prolonged exposure can lead to, among other things, chronic respiratory diseases

"bloated", misshapen, difficult to stack bags because a lot of air is trapped during the bagging process

We have the solution for efficient, clean and compact bagging of carbon black. We offer you a system and bags that are completely tailored to Carbon Black.

Bags:

Optimized packaging for Carbon Black

The Clean Cycle only works perfectly if the packaging material meets the high requirements of the system and product. Together with our customers and the manufacturer, we develop dy-pack paper bags that optimally fit the product and machine offer the highest possible bagging efficiency and optimal product protection.

The advantages are:

Up to 50 percent time and cost savings through leaner development and validation processes

Maximum utilization of the transport space without abrasion damage through optimization of the packaging concept

Optimal process coordination: No more disputes about responsibilities and responsibilities between machine and bag manufacturers

Reduction in complaint costs

Increase brand reputation

System:

GREIF-VELOX

VeloVac

With the VeloVac technology from Greif-Velox, carbon Black manufacturers worldwide rely on dust-free and efficient bagging in a completely sealed vacuum chamber. This results in measurable advantages for users.

Reduction of transport and logistics costs by up to 75 percent and reduction of the CO2 footprint by four times by compacting carbon black

Saving cleaning costs and protecting employees thanks to completely dust-free bagging

Guaranteeing a high-purity product (e.g. necessary in battery production) without contamination thanks to bagging in a closed vacuum chamber

Reduction of transport damage thanks to stably stackable bags and an even pallet appearance

Lower maintenance costs and space savings compared to the use of pump packers (e.g. elimination of complex maintenance and calibration of the vacuum rollers)

Higher workplace ergonomics and employee savings through automation (use of robots that, for example, remove the bags from the vacuum chamber)

Find the right contact person

Direct contact to GREIF-VELOX or competent trading partner at your location:

You will find the right contact person for your request here.