News at GREIF-VELOX

Valuable information about current trends and developments for companies, engineers, technicians and partners who want to stay up to date on topics related to filling systems and packaging machines.

Discover our collection of specialist articles and industry news that provide a good insight into our expertise and focus areas.

The R-DOS Essential from GREIF-VELOX is a compact, semi-automatic filling system for flexible, economical and safe liquid filling.

With a Christmas raffle in December 2024, the employees of GREIF-VELOX together with the management collected 1,750 euros for Tafel Lübeck.

In view of the growing demand for efficient packaging solutions in the Gulf region, GREIF-VELOX has entered into a strategic partnership with Packme Mena FZ LLC.

With the VeloFlexLabeler, GREIF-VELOX introduces an innovative, fully automated solution that meets the highest demands for precision, flexibility, and safety with absolute reliability.

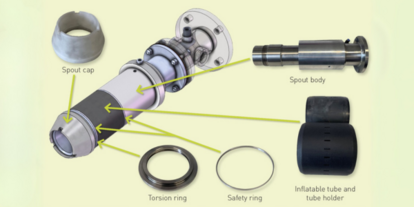

Achieve up to 125,000 cycles with GREIF-VELOX’s innovative inflatable tube seal. Reduce downtime, cut costs, and streamline replacements by 75%. Boost productivity today!

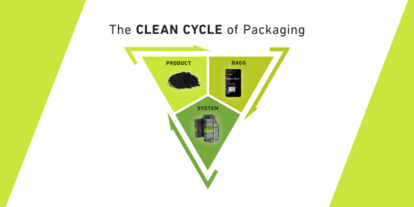

GREIF-VELOX presents the CLEAN CYCLE of Packaging for efficient bagging of Carbon Black

Packaging machinery specialist GREIF-VELOX gains a new partner in the USA with Specialty Equipment.

After showcasing the GREIF-VELOX VeloVac Full-Line and the A-DOS-P1 filling machine, users of the Vuframe app can now explore the Pneumatic Packer BVP from any angle on their smartphones.

Following our successful launch of the VeloVac Full-Line in 3D and 360-degree view accessible via the Vuframe app on smartphones and tablets, we now present one of our filling machines: the A-DOS-P1.

With PureVacSpout we have developed a patented solution to remove dust residues on filling spouts and thus prevent contamination of valve bags or pallets.

Management change at the top of the Lübeck-based packaging machine manufacturer Greif-Velox: Since February 1, 2024, the previous Managing Director Sales, Sebastian Pohl, has joined the management team together with Thorsten Köll. The previous Managing Director Ralf Drews is leaving the company.

Greif-Velox is further expanding its sales network in Europe: In a strategic partnership with Sopack s.r.o., the packaging machine manufacturer and the Czech sales and production company are using synergy effects to position Greif-Velox's innovations on the Czech, Slovakian, Polish and Hungarian markets.