Overall Equipment Effectiveness (OEE): Increase production output with overall plant effectiveness

Overall Equipment Effectiveness (OEE) is a key metric used by manufacturing companies to measure the efficiency of their production facilities. OEE assesses losses in the areas of availability, performance, and quality, indicating how effectively a facility is utilized. This metric serves to monitor and identify bottlenecks and provides a foundation for data-driven decisions regarding process improvement.

Thus, OEE is an important KPI (Key Performance Indicator) in the industry, as it creates transparency about the actual use of production capacities.

Specifically, OEE helps develop effective measures to reduce downtime, optimize performance, and improve product quality. Poor OEE values result in losses in the form of downtime, production delays, and quality defects.

An extended metric of Overall Equipment Effectiveness is Total Effective Equipment Productivity (TEEP), which takes into account the entire available time of a facility—regardless of planned or unplanned breaks.

What does the Overall Equipment Effectiveness (OEE) metric express?

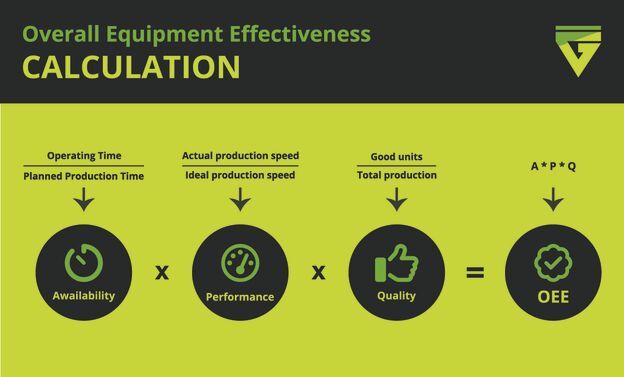

Overall Equipment Effectiveness (OEE) measures the effectiveness of a production facility based on three parameters: availability, performance rate, and quality.

The OEE metric captures and quantifies all losses that affect the production process. It answers the question of how effectively a facility can actually be utilized by analyzing operating time (=availability), speed (=performance rate), and the quality of the produced output.

OEE calculates an overall value that summarizes the efficiency of the entire production process in a percentage. This metric is used both to monitor the current performance of the facility and as a driver for continuous improvement by identifying sources of loss or waste in the production processes.

What is the significance of OEE as a KPI for industrial production?

OEE as a KPI monitors current equipment performance and provides valuable insights for strategic planning and continuous process improvement within production operations.

Specifically, OEE plays a central role as a Key Performance Indicator (KPI) in industrial production by offering a comprehensive overview of a facility's productivity. By capturing all potential losses, it quantifies overall equipment efficiency, which is a significant advantage in measuring operational effectiveness. Companies can use the OEE value to precisely determine how much of the available production capacity is actually being utilized.

Another important aspect of OEE as a KPI is benchmarking. Production facilities use the OEE metric to compare their equipment efficiency against internal goals or industry-specific best practices. However, it is important to note that OEE should not be used to compare different facilities or locations, as varying operating conditions can influence the results.

Furthermore, OEE serves as a driver for continuous improvement. By accurately identifying and quantifying losses in availability, performance, and quality, targeted measures can be developed to enhance production efficiency. Thus, OEE initiates process optimizations and positively contributes to sustainable efficiency increases.

Another significant aspect of OEE as a KPI is the transparency it provides over the production process. It helps to highlight bottlenecks and inefficient workflows, allowing companies to proactively address these shortcomings in production. The detailed analysis systematically identifies the causes of inefficiencies and enables their rectification.

What formula is used to calculate Overall Equipment Effectiveness (OEE)?

The calculation of Overall Equipment Effectiveness (OEE) is performed by multiplying the three factors availability, performance, and quality, which are each expressed as a percentage. The formula is as follows:

OEE = Availability × Performance × Quality

Each of these factors is calculated as follows:

Availability measures how much of the planned production time is actually utilized:

Availability = × 100

Performance compares the actual production speed with the ideal speed:

Performance = × 100

Quality evaluates the proportion of good units produced to the total production:

Quality = × 100

The OEE gives a total percentage which reflects the efficiency of the production process.

What is the OEE availability factor?

The OEE factor availability measures how much of the planned production time a facility is actually used productively.

It indicates how often a facility is operational in relation to the available time, taking into account all unplanned downtime, such as technical failures, material shortages, or other unexpected interruptions.

The availability is calculated using the following formula:

Availability = × 100

A high availability indicates that the facility experiences few interruptions during the planned production time.

A low value suggests that frequent downtimes occur, caused by unplanned maintenance or disruptions.

The identification and minimization of these losses are prerequisites for the efficiency improvement of a production facility and are made transparent through OEE measurement.

What is the OEE performance factor?

The OEE factor performance measures the actual production speed of a plant compared to the ideal speed.

This factor captures losses caused by reduced speed and minor, unrecorded stops. The goal is to determine how efficiently a machine operates concerning its possible maximum performance.

The calculation of performance is based on the following formula:

Performance = × 100

A high performance rate means that the production speed is close to the ideal speed. Low values indicate performance issues, such as speed losses caused by technical disruptions, human errors, or inefficient process flows.

Thus, the OEE performance factor identifies the bottlenecks and delays in the production process that can be minimized through optimization measures.

What does the OEE quality factor mean?

The OEE factor of quality assesses the proportion of defect-free products produced during the manufacturing process.

It indicates what percentage of the total units produced meets quality requirements. The quality factor is crucial for identifying and minimizing losses due to scrap and rework.

The formula for calculating the OEE quality factor is as follows:

Quality = × 100

A high quality indicates that almost all produced units are defect-free and require no rework.

Low values indicate quality problems that lead to additional costs due to material losses or increased processing time.

The OEE quality factor aims to support continuous improvements in production quality by uncovering sources of errors and initiating process optimizations.

Calculation example: How is the OEE calculated for a single machine?

To calculate the OEE for a single machine or individual system, the three factors availability, performance, and quality must be calculated and multiplied together.

Example scenario:

A single machine has the following data over a planned production period of 8 hours (480 minutes):

- Operating time (after deducting unplanned downtime): 400 minutes

- Ideal production speed: 50 units per minute

- Actual production speed: 45 units per minute

- Units produced: 18,000

- Good units (without defects): 17,000

Availability Calculation:

Availability = × 100 = 83.33%

Performance Calculation:

Performance = × 100 = 90%

Quality Calculation:

Quality = × 100 = 94.44%

OEE Calculation:

OEE = 83.33% × 90% × 94.44% = 70.83%

The individual machine in this example achieves an OEE of 70.83%. This value indicates that the machine has effectively utilized 70.83% of its theoretically possible production capacity.

Calculation example: How is the OEE calculated for a chained installation?

The calculation of Overall Equipment Effectiveness (OEE) for a linked production line follows the same basic formula as for individual machines, but with additional calculation effort, as losses at each station of the production line accumulate.

Here, OEE is applied to the entire line by calculating the efficiency of each station in terms of availability, performance, and quality and then combining them.

Example scenario:

Assume a full-line system consists of three linked machines (Stations A, B, and C). The following data is provided for each station:

- Availability:

- Station A: 90%

- Station B: 85%

- Station C: 80%

- Performance:

- Station A: 95%

- Station B: 90%

- Station C: 85%

- Quality:

- Station A: 98%

- Station B: 95%

- Station C: 97%

Step 1: Calculation of OEE for each station:

The OEE for each station is calculated individually by multiplying the factors of Availability, Performance, and Quality:

- OEE Station A:

OEEA = 90% × 95% × 98% = 83.61%

- OEE Station B:

OEEB = 85% × 90% × 95% = 72.68%

- OEE Station C:

OEEC = 80% × 85% × 97% = 65.96%

Step 2: Calculation of the total OEE for the linked system:

To calculate the total OEE of the linked system, the overall productivity of each station in the chain is combined. Since the output of the entire line is limited by the weakest station, the station with the lowest OEE determines the overall effect on the line.

Thus, the total OEE will be close to the lowest value, which is around 65.96%.

This calculation shows that the performance of the linked system is heavily influenced by the least efficient station, and optimizing individual stations can significantly improve the overall line performance.

Calculation example: How is the OEE calculated taking into account downtimes?

Downtime has a significant impact on Overall Equipment Effectiveness (OEE), as it directly reduces the availability of a machine. In this example, OEE is calculated taking into account planned and unplanned downtime.

Example scenario:

Let's assume a machine has a planned production time of 8 hours (480 minutes), but both planned and unplanned downtimes occur:

- Planned downtime: 40 minutes (scheduled maintenance and breaks)

- Unplanned downtime: 60 minutes (machine failure)

- Operating time: 480 minutes – 100 minutes (planned and unplanned downtime) = 380 minutes

- Ideal production speed: 50 units per minute

- Actual production speed: 45 units per minute

- Produced units: 17,100

- Good units: 16,500

Calculation of Availability:

Availability accounts for the impact of downtimes:

Availability = 380 480 × 100 = 79.17%

Calculation of Performance:

Performance shows the actual production speed compared to the ideal speed:

Performance = 45 50 × 100 = 90%

Calculation of Quality:

Quality measures the proportion of defect-free products:

Quality = 16,500 17,100 × 100 = 96.49%

Calculation of OEE:

The OEE is derived by multiplying the three factors:

OEE = 79.17% × 90% × 96.49% = 68.67%

This example demonstrates that unplanned downtimes have a significant impact on Overall Equipment Effectiveness. The OEE in this case is 68.67%, highlighting potential areas for improvement, particularly in reducing unplanned downtime.

Calculation example: How do quality losses affect OEE?

Quality losses directly affect the quality factor of the OEE. Every unit that does not meet the specifications is counted either as scrap or rework. These losses reduce the percentage of defect-free products, thereby lowering the overall equipment effectiveness.

Example Scenario:

A facility produces 20,000 units in a given time period. Of these, 1,000 units are defective and must either be reworked or discarded.

Calculation of the OEE Quality Factor:

Quality = × 100

Quality = × 100 = 95%

Calculation of the Overall OEE:

Assuming availability and performance are constant at 90%, the overall OEE is calculated as follows:

OEE = 90% × 90% × 95% = 76.95%

In this example, quality losses reduce the OEE by about 5%. This shows that quality issues have a significant impact on overall equipment effectiveness, as each loss directly affects the final efficiency of production.

Calculation example: How is the availability rate calculated in a multi-stage production line?

In a multi-stage production line, the availability of each individual production stage influences the overall availability rate of the production line. Losses due to downtime or unplanned maintenance in any of the stages can slow down or stop the entire line.

Example Scenario:

A production line consists of three stages (Stations A, B, and C), with each station having its own availability rate:

- Availability Station A: 92%

- Availability Station B: 85%

- Availability Station C: 88%

Calculation of Overall Availability Rate:

The overall availability of the line is calculated by multiplying the availability rates of the individual stations:

Overall Availability = Availability A × Availability B × Availability C

Overall Availability = 0.92 × 0.85 × 0.88 = 0.687 (or 68.7%)

In this case, the availability rate of the entire production line is 68.7%. This shows that losses in a single stage can significantly impact the overall effectiveness of the production line. The availability rate thus provides insight into potential bottlenecks and the need for optimizations within the production line.

What is a good OEE?

A good OEE value strongly depends on the specific industry and production process, as well as the specific requirements of the production process.

The following OEE values are considered guidelines:

- Good OEE: 85% or more

- Average OEE: 60-85%

- Low OEE: Below 60%

Continuous processes often have higher OEE target values, up to 95%, as they have less downtime and setup times.

In discrete manufacturing environments, an OEE value of 85% is considered desirable, with 90% availability, 95% performance, and 99% quality regarded as ideal target values.

Good to know: What are continuous and discrete manufacturing environments?

A continuous manufacturing environment refers to production processes where products are produced in a continuous flow and in large quantities. This type of manufacturing is often used in industries where raw materials are continuously processed and converted into standardized end products. Examples of continuous manufacturing include the chemical industry, food industry, and petrochemical industry.

A discrete manufacturing environment refers to production processes where individual, clearly distinguishable products are produced. These products are typically manufactured in quantities and can be easily counted and distinguished from one another. Examples of discrete manufacturing include the production of cars, electronics, furniture, or household appliances. In such environments, production processes are often divided into various work steps, each producing specific components or assemblies that are eventually combined into an end product.

It should be emphasized that the evaluation of OEE should always be specific to the operation. Different facilities, product requirements, production methods, material types, and packaging types mean that a uniform benchmark is not always sensible. For example, in a facility with frequent product changes, an OEE of 75% can be very good, while a higher value is expected in a continuous process.

How can OEE be improved?

OEE can be improved through various strategic approaches. The main measures include Total Productive Maintenance (TPM), Lean Management, Automation, and Digitalization in the context of Industry 4.0. Each of these methods contributes in specific ways to reducing losses and enhancing the efficiency of production facilities.

Total Productive Maintenance (TPM)

TPM is a proven method for maximizing the availability of equipment and minimizing unplanned downtimes. The goal of TPM is to integrate maintenance activities into the daily production process so that machines are continuously kept in optimal condition.

This includes:

- Autonomous Maintenance: Machine operators perform simple maintenance tasks themselves, which reduces downtime.

- Planned Maintenance: Regular, preventive maintenance prevents unplanned failures and improves OEE through higher machine availability.

Lean Management

Lean Management focuses on minimizing waste in all areas of a production operation. By applying principles such as Just-in-Time, 5S, and Continuous Improvement (Kaizen), processes are streamlined, and resources are utilized more efficiently. When referring specifically to production, this is often called Lean Production. In terms of OEE, this means:

- Quick Changeover Times: Methods like SMED (Single-Minute Exchange of Die) minimize changeover times, which increases availability.

- Flow Optimization: Optimizing workflows leads to higher production output and reduces speed losses.

Automation

Automating production processes increases the performance and quality of production by minimizing human errors and ensuring consistent production speeds.

By using automated control systems, production bottlenecks and minor downtime can be better monitored and corrected. Automation of production positively impacts OEE by maximizing performance and avoiding quality losses through consistent precision.

Digitisation / Networking

Digitalization allows for real-time collection and analysis of production data. With the help of IoT sensors and big data analytics, companies gain deeper insights into the causes of losses and can take proactive measures to improve OEE. Digital dashboards and reporting platforms facilitate tracking of machine conditions and production metrics, ensuring targeted optimization in line with Industry 4.0.

Benefits of OEE: How can overall plant effectiveness improve production processes?

OEE identifies bottlenecks in the production process by making performance in the areas of availability, performance, and quality transparent. Companies can accurately identify which machines or production stages are operating inefficiently and where the largest losses occur.

For example, a low availability rate often reveals machine downtimes, while a low performance rate indicates speed issues. Identifying such weaknesses allows targeted measures for improvement and elimination of bottlenecks.

OEE provides a basis for data-driven decisions, as the metric summarizes all relevant production data. Companies can use this data to steer their process optimizations more precisely. Continuous monitoring of OEE values allows for quick identification of patterns and recurring issues. This enables informed decisions to optimize production processes and sustainably increase efficiency.

The OEE analysis reveals improvement potential in maintenance and quality assurance. By accurately capturing machine availabilities and the quality of produced goods, companies can develop preventive maintenance strategies.

Total Productive Maintenance (TPM) and other preventive measures can be specifically introduced to minimize failures and increase availability. At the same time, monitoring the quality rate ensures that production errors and scrap can be effectively reduced.

Practical example: Improving OEE with the VeloVac gross vacuum packer from GREIF-VELOX

The VeloVac is a vacuum bagging system specially developed by GREIF-VELOX for bagging extremely light, dusty or difficult-to-handle lightweight materials. The system uses a closed vacuum chamber to bag lightweight materials such as powder efficiently and cleanly. With the VeloVac, there is concrete potential for improved OEE.

Higher availability

The VeloVac extends productivity times and reduces downtimes.

Remote support allows up to 95% of faults to be diagnosed and rectified remotely. This minimises unplanned downtime and enables the system to be restarted quickly.

The integrated anhydrous vacuum pump increases the reliability of the system and therefore its availability, as it generally does not cause any technical faults due to low wear. Any waiting times due to long journeys by technicians, for example, are eliminated.

Another key technology for maximising the system availability of the VeloVac is the ‘Clean in Place (CIP)’ function, which enables the system to be cleaned without having to be dismantled or disassembled. This significantly shortens planned maintenance cycles and minimises the duration of necessary production interruptions. Particularly in sectors with strict hygiene regulations, such as the chemical and food industries, Clean in Place significantly reduces the time required for cleaning.

Stronger performance

With an output of up to 90 bags per hour, the VeloVac has a high bagging rate. The VeloVac achieves this benchmark thanks to precise and automated control processes during bagging.

The storage of machine parameters for different lightweight materials enables fast and error-free material changeovers, minimising set-up times and allowing production to continue almost seamlessly. This maximises the actual operating time of the system and reduces performance losses during the changeover.

In addition, the perfect coordination of system, container (bag), material and end product (= the so-called clean circle) ensures a trouble-free process that significantly increases the process speed.

Higher quality

The Velovac's closed vacuum bagging system completely eliminates air pockets, optimising bag compaction and preventing stability problems. This minimises the risk of damage during storage and transport.

The ultrasonic sealing also ensures tightly sealed bags. This ensures product integrity and there is no loss of material or contamination of the material itself. This guarantees maximum product safety, especially in sensitive sectors such as the chemical industry.

The VeloVac also creates an improved working and production environment thanks to its dust-free operation. The innovative system reduces dust generation to 0%.

What are the disadvantages of poor OEE?

A poor OEE leads to significant losses in important production metrics, expressed as: downtime, production delays, and quality issues. Each of these categories significantly reduces the efficiency of the production facility.

- Downtime: Unplanned outages or long setup times reduce the availability of the equipment, thereby decreasing productive operating time.

- Production delays: Reduced production speeds and frequent interruptions lead to lower equipment performance.

- Quality issues: A high error rate and product scrap negatively impact quality and result in additional rework.

Typical waste types in production facilities that exhibit or cause low OEE include:

- Overproduction: Producing more than the actual needed demand.

- Waiting times: Equipment or workers waiting for the next step in the process, leading to delays.

- Unnecessary transport: Movements of materials that do not create direct value increase cycle times.

- Faulty processes: Erroneous production steps lead to rework and scrap, reducing quality and consuming additional resources.

What is Total Effective Asset Productivity (TEEP)?

Total Effective Equipment Productivity (TEEP) is a metric that measures the actual utilization of the total available production time of a facility.

TEEP thus assesses overall equipment efficiency by also including times outside of planned production, such as weekends or holidays, in the calculation.

TEEP helps companies understand how effectively their machines are utilized throughout the year and whether there is any untapped potential.

What are the differences between OEE and TEEP?

The main difference between OEE and TEEP lies in the consideration of planned and unplanned production times.

While OEE measures the efficiency of a machine during planned production time, TEEP analyzes usage over the entire available time, regardless of planned production breaks or downtimes.

This makes TEEP a more comprehensive metric, as it provides insight into how much potential a facility is truly realizing.