ValvoCut product data

| Containers | Valve bags made of paper, PE, PP |

|---|---|

| Industry | Chemicals, petrochemicals, food |

| Suitable systems | BVP/BVPV air packers, BVT, VELOVAC Vacuum packer, VELOPACK robot palletizing |

| Accessories & extensions | Valvomat, ValvoSeal |

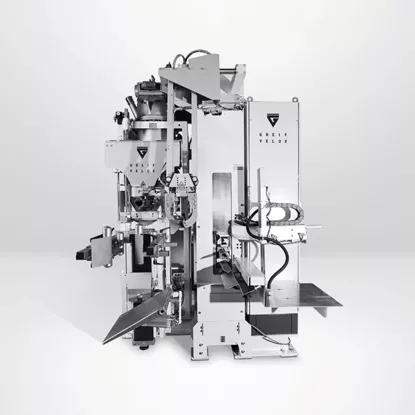

ValvoCut: the innovation for clean and precise bag cutting

Clean and precise cutting

Additional costs due to manual cutting and inaccurate cuts

ValvoCut minimizes manual effort and ensures precise and clean cutting of the valve protrusion, which reduces production costs.

High error rate and quality problems due to manual cuts

By automatically cutting, ValvoCut significantly reduces the error rate and ensures consistent bag quality.

Production interruptions due to time-consuming manual rework

ValvoCut's automated processes increase efficiency and lead times, resulting in higher productivity and less downtime

High cleaning and maintenance costs due to unclean cuts

ValvoCut ensures clean cuts, reduces leaks and contamination and thus also the associated cleaning and maintenance costs

As part of a closed production system, our filling systems go far beyond the pure filling function: They form an integral part of an overall system that fits seamlessly into and complements existing production lines.

Our full-line systems are able to meet complex requirements from container provision to filling to post-processing and storage, which makes us a holistic system provider in production technology. The focus is on individual adaptation to ensure optimal integration into the respective operational processes.

With standard solutions you save money.

With individual solutions you earn money.

Our philosophy at Greif-Velox is to offer individually tailored solutions instead of standard products.

Each filling system is precisely tailored to the needs and processes of our customers to enable rapid integration into existing product lines or the development of a fully coordinated full-line system.

We attach great importance to precision, safety and automation in order to increase our customers' production efficiency with maximum flexibility.

Find the right contact person

Direct contact to GREIF-VELOX or competent trading partner at your location:

You will find the right contact person for your request here.

Suitable GREIF-VELOX systems for valve bag filling