The customer

Reagens Deutschland GmbH, with its production sites in Lohne and Loxstedt, is part of the internationally active Reagens Group. The company is one of the world's leading manufacturers of PVC stabilizers and other thermoplastic polymers.

Reagens supplies the plastics industry with a wide range of customized additives and has an international presence via a global sales network.

The starting point

At the Loxstedt site, Reagens used to fill micronized waxes and wax blends using two manual systems. These slow-flowing products have a strong tendency to agglomerate, which led to regular production delays and time-consuming cleaning - especially when changing products. The existing systems not only caused long downtimes, but also product losses of up to one kilogram per batch.

The request

The aim was to modernize and automate the filling processes in such a way that cleaning times in particular could be drastically reduced and downtimes minimized. The solution also had to be able to be integrated into the existing production areas. The requirements for the new system included:

- Minimal product residue in the boiler

- Short cleaning cycles for product changes

- Easy visual inspection and accessibility of the relevant components

- Compact design for integration into existing production environments

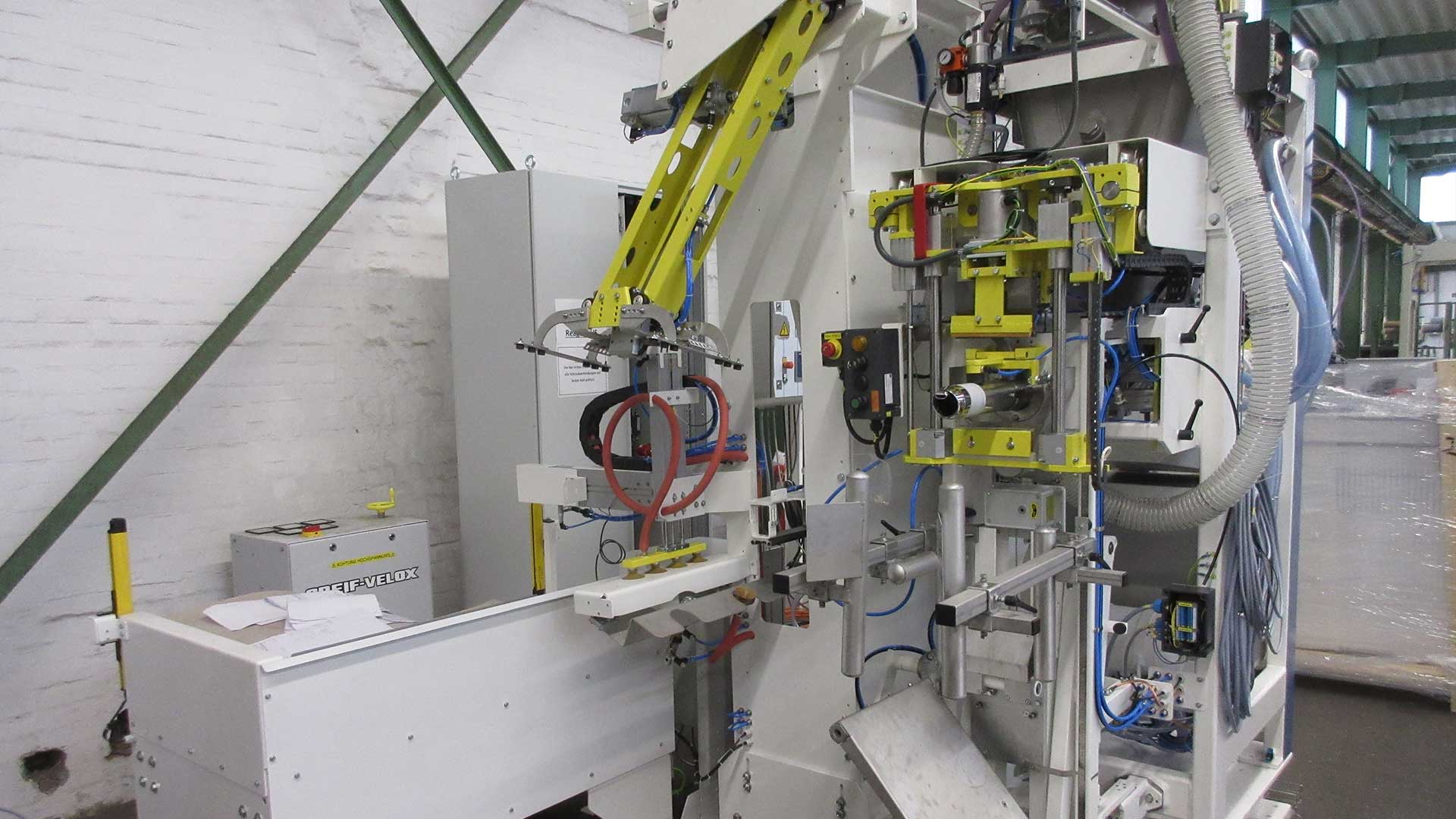

The solution

Reagens opted for two BVP gross pneumatic packers from GREIF-VELOX. This system, specially developed for filling powders and fine-grained products, offers decisive advantages with its innovative residual emptying function:

- Thanks to the new bowl shape and an integrated air flushing system, less than 12 grams of product remain in the bowl after emptying.

- This reduced the cleaning time from 30 minutes to just 5 minutes - a time saving of 80 percent.

- Thanks to the pneumatic opening device, a visual inspection can be carried out quickly and easily after each emptying.

- The type-specific machine parameters can be saved and called up each time the product is changed - this also increases efficiency.

The result: significant time savings and greater efficiency for Reagens

The changeover to the GREIF-VELOX BVP system led to a significant improvement in production processes at Reagens - especially with the multiple product changeovers required each day. Downtimes for cleaning were reduced by 80 % and product loss was virtually eliminated. At the same time, the company was able to continue using its existing premises, as the BVP system is very compact despite its automation.

“We couldn't believe our eyes,” says Heiko Sievern, Technical Manager at Reagens. “The air packer was swept clean despite the highly adhesive and poorly flowing products - a huge win!”

The long-standing collaboration with GREIF-VELOX and the personal commitment of the engineers, who are deeply involved in the production processes, have made all the difference: “The engineers are fully involved in our production processes and point out opportunities for improvement in a collegial manner.”

The air packer was swept clean despite the highly adhesive and poorly flowing products - a huge win!

Heiko Sievern,

Technical Manager at Reagens Deutschland GmbH

80 % shorter cleaning time for product changes

Almost complete residual emptying (< 12 g product in the boiler)

Simple visual inspection and cleaning

Compact design for continued use of existing production areas

Storage of type-specific parameters for efficient conversions