Suitable filling processes for canister filling

Below bunghole filling

Specially developed for closed containers where the liquid is supplied through a bunghole. This variant is suitable for non-foaming and uncomplicated liquids and ensures precise filling.

Above level filling

Suitable for uncomplicated, non-foaming products. With this method, the liquid comes out of the dosing element above the liquid level, ideal for open and closed (bunghole) containers.

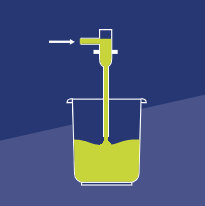

Below level filling

This method is suitable for foaming products or if explosive gases can be released during filling. The liquid exits below the liquid surface, which prevents foam and electrostatic charges in flammable materials.

GREIF-VELOX solutions from the

practice for pallet filling

Fully automatic pallet filling system A-DOS-P1

The A-DOS-P1 is a fully automatic portal filling system designed for filling liquids into containers on pallets. With a capacity of up to 40 drums (200 l) or 15 IBCs (1000 l) per hour, the system offers an efficient and safe solution for the chemical and petrochemical industries as well as for the food industry. The pallets are automatically fed, the containers are opened, filled, closed and palletized.

Advantages

Flexibility and adaptability: Suitable for a wide range of liquids, including foaming substances and adaptable for use in Ex areas Zone 1. The system offers a high degree of flexibility in the types of containers that can be filled.

Environmental protection and safety: Integrated inerting and overfill shutdown minimize the risk of environmental damage and protect employees.

Automation: The entire filling process is automated, which increases efficiency and reduces the error rate.

Options

Extended safety features: Additional safety devices such as inerting, overfill shutdown or drip trays.

Higher automation: Adjustments such as controlled valve upward movement or motorized valve base height adjustment.

Special equipment and material selection: Available in stainless steel and with special materials for product-contact parts.

Integration and customization Possibility of customization to customer-side product feeders and integration into customer-side control systems.

Coordinate filling system K-DOS

The K-DOS coordinate filling system from GREIF-VELOX is a semi-automatic system that can handle up to 60 drums per hour (200l) or 18 IBCs per hour (1000l). This system is characterized by its flexibility in handling various containers and products. The operation includes the manual feeding of IBCs or pallets, the manual opening of the containers, semi-automatic positioning of the filling valve using a joystick and automatic inerting and filling. The containers are closed manually.

Advantages

Flexibility and adaptability: The K-DOS system enables the filling of various liquids, including foaming substances, and is suitable for use in Zone 1 hazardous areas. It offers great flexibility in the types of containers that can be filled and does not require palletizing full containers, which makes it easier to adapt to local production conditions.

Options

Advanced safety features: Optional safety devices such as inerting, overfill shut-off and collecting trays increase operational safety.

Higher automation: The modular system makes adjustments such as controlled upward valve movement or motorized valve base height adjustment possible.

Special equipment: The system offers options for improved cleaning and is available in stainless steel and with special materials for parts in contact with the product.

Integration into existing systemsIt can be integrated into customer product feeds and control systems to ensure optimal integration into existing production environments.

Automatic filling system K-DOS-A

The K-DOS-A from GREIF-VELOX is a fully automatic coordinate filling system, designed for the efficient filling of up to 60 drums (200l) per hour or 18 IBCs (1000l) per hour. This system offers automatic positioning of the filling valve using high-precision control technology, automatic inerting and filling as well as manual closing of the containers, with the drums being opened and closed manually. The feeding of the IBCs or pallets can be supported both manually and automatically using integrated conveyor technology.

Advantages

High automation and precision: Automated processes for positioning, inerting and filling increase the efficiency and accuracy of the system.

Adaptability and safety: The system is suitable for use in hazardous areas Zone 1 and offers flexibility when handling different types of containers. Safety devices such as inerting and overfill shut-off increase operational safety.

Efficient integration into production lines: Thanks to its modular design, the K-DOS-A can be seamlessly integrated into existing production environments, supported by options for improved cleaning and pneumatic sealing tools.

Options

Advanced safety features: Integrated safety options such as inerting and overfill shutdown that ensure compliance with strict safety standards.

Automated feeding: Options for automating the feeding of IBCs or pallets through conveyor technology to minimize manual labor.

Material selection and cleaning options: Stainless steel system for improved hygiene and longevity; special cleaning systems to maintain product quality and production hygiene.

Adaptation and integration Ability to adapt to specific customer specifications and seamless integration into existing control systems and production lines.

Radial filling system R-DOS

The R-DOS from GREIF-VELOX is a semi-automatic radial filling system, designed for filling up to 55 drums (200 l) per hour or 18 IBCs (1000 l) per hour. This system enables the manual feeding of pallets or IBCs and offers manual opening of the containers, manual positioning of the filling valve, automatic inerting and filling, as well as manual closing of the containers.

Advantages

Flexibility and adaptability: Suitable for a variety of liquids including foaming substances and adaptable for use in Zone 1 hazardous areas. The system offers a high level of flexibility fillable container types and does not require palletizing full containers.

Options

Advanced safety features: The system can be equipped with additional safety devices such as inerting, overfill shut-off or collecting trays.

Higher automation: The modular system makes adjustments such as controlled valve upward movement or motorized valve base height adjustment possible.

Special equipment and material selection: The system offers options for improved cleaning and is available in stainless steel and with special materials for parts in contact with the product.

Integration and adaptation Ability to adapt to customer product feeds and integration into customer control systems to ensure optimal integration into existing production environments.

Semi-automatic filling system R-DOS Essential

The R-DOS Essential from GREIF-VELOX is a cost-effective, user-friendly dosing solution for bulk materials. With its plug & play design and optional 2-weighing system, it offers flexibility and short delivery times of just four weeks. Ideal for getting started with precise dosing processes.

Advantages

Simple integration: Plug & fill principle enables fast commissioning and intuitive handling

Fast availability: Delivery within 4 weeks - minimised waiting times for your production

ATEX certification: Safe use in potentially explosive areas (Zone 0/1)

Options

Version for explosion protection requirements

Product feed on upright with pilot ball valve and product hose

Valve parking stand for efficient handling

Screwdriver on swivelling arm with additional clincher

Optional second scale for precise weight measurement

By combining pallet filling systems for liquids from GREIF-VELOX with our high-performance robot palletizers, companies maximize their production output. Seamless integration of container palletization into filling processes ensures maximum throughput and production efficiency.

Palletizing robots in detail

You save money with standard solutions.

You earn money with individual solutions.

Our philosophy at Greif-Velox is to offer individually tailored solutions instead of standard products.

Each liquid filling system is tailored precisely to the needs and processes of our customers to enable rapid integration into existing product lines or the development of a completely coordinated full-line system.

We attach great importance to precision, safety and automation in order to increase our customers' production efficiency with maximum flexibility.

Maximum efficiency and flexibility through full-line systems

Specific filling requirements require individual system solutions

Greif-Velox filling systems for liquids are specifically designed to meet the diverse requirements in industries such as chemicals, food and petrochemicals.

Custom products for special needs

Temperature-sensitive liquids: Realization of heated filling systems GMP-compliant solutions: Developed specifically for the food and pharmaceutical sectors Personnel savings: Processes optimized through automation.

Precision in every drop

Product-specific valves: ensure accurate dosing Adaptation to container types: flexibility for canisters, drums and IBCs Automatic opening and closing: ensures the integrity of the end product.

Purity and security

Clean production environments through integrated solutions Increased efficiency and safety through systems made of stainless steel or plastic.

Holistic system solutions through full-line filling systems

As part of a closed production system, our filling systems for liquids go far beyond the pure filling function: They form an integral part of an overall system that fits seamlessly into existing production lines and complements them.

Our full-line systems are able to serve complex requirements from container preparation and filling to post-processing and storage, which makes us a holistic system provider in production technology.

The focus is on individual adaptation to ensure optimal integration into the respective operational processes.

Find the right contact person

Direct contact to GREIF-VELOX or competent trading partner at your location:

You will find the right contact person for your request here.