Product data K-Dos

| Automatic filling of palletized containers using the Below bunghole filling, Below level filling or Above level filling process | |

|---|---|

| Medium | Low to high viscosity products (1 to 50,000 mPas at 20°C) |

| Industry | Chemistry, petrochemicals, food |

| Performance | up to 60 drums per hour or 18 IBC per hour |

Transform your filling processes with the K-DOS-A

Benefit from automated filling

Tedious manual settings and positioning

Automated positioning and filling increase speed and reduce manual work.

High risk of contamination and chemical reactions

Automatic inerting increases product and work safety.

Difficult handling of different types of liquids

Flexible customization options enable versatile use.

Costly production losses in hazardous areas

Certified safety technologies guarantee reliable operations in Ex zones.

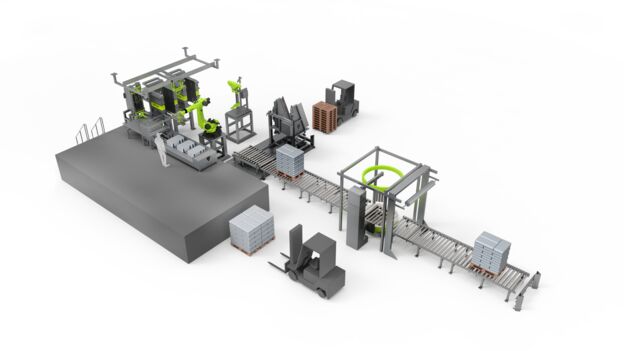

As part of a closed production system, our filling systems go far beyond the pure filling function: they form an integral part of an overall system that fits seamlessly into existing production lines and complements them.

Our full-line systems are able to serve complex requirements from container preparation and filling to post-processing and storage, which makes us a holistic system provider in production technology. The focus is on individual adaptation in order to ensure optimal integration into the respective operational processes.

Save money with standard solutions.

Earn money with individual solutions.

Our philosophy at Greif-Velox is to offer individually tailored solutions instead of standard products.

Each liquid filling system is tailored precisely to the needs and processes of our customers to enable rapid integration into existing product lines or the development of a completely coordinated full-line system.

We attach great importance to precision, safety and automation in order to increase our customers' production efficiency with maximum flexibility.

Find the right contact person

Direct contact to GREIF-VELOX or competent trading partner at your location:

You will find the right contact person for your request here.

Further GREIF-VELOX pallet filling systems