World first: ValvoCare from GREIF-VELOX guarantees clean bags and pallets during bagging

Maximum customer satisfaction and no complaint costs thanks to the highest possible process reliability: The ValvoCare gripper Velox prevents the contamination of filled bags and pallets by the product remaining in the valve protrusion behind the seal, thus enabling a guaranteed clean bagging and palletizing result. In order to reduce unplanned downtimes, it automatically and proactively informs you when wear parts need to be replaced and can even reorder them automatically.

When bagging ultra-light materials such as carbon black, color pigments, pesticides or toxic powders, cleanliness and safety are paramount. To avoid health risks and complaint costs due to contaminated bags, Greif-Velox has revolutionized the sealing process. The world first Greif-Velox ValvoCare with smartValvoCut combines maximum cleanliness and employee safety with minimum operating costs. Customer complaints due to dirty, contaminated pallets are proactively prevented and operating, spare parts and consumables costs are reduced thanks to automatically adjusted process parameters.

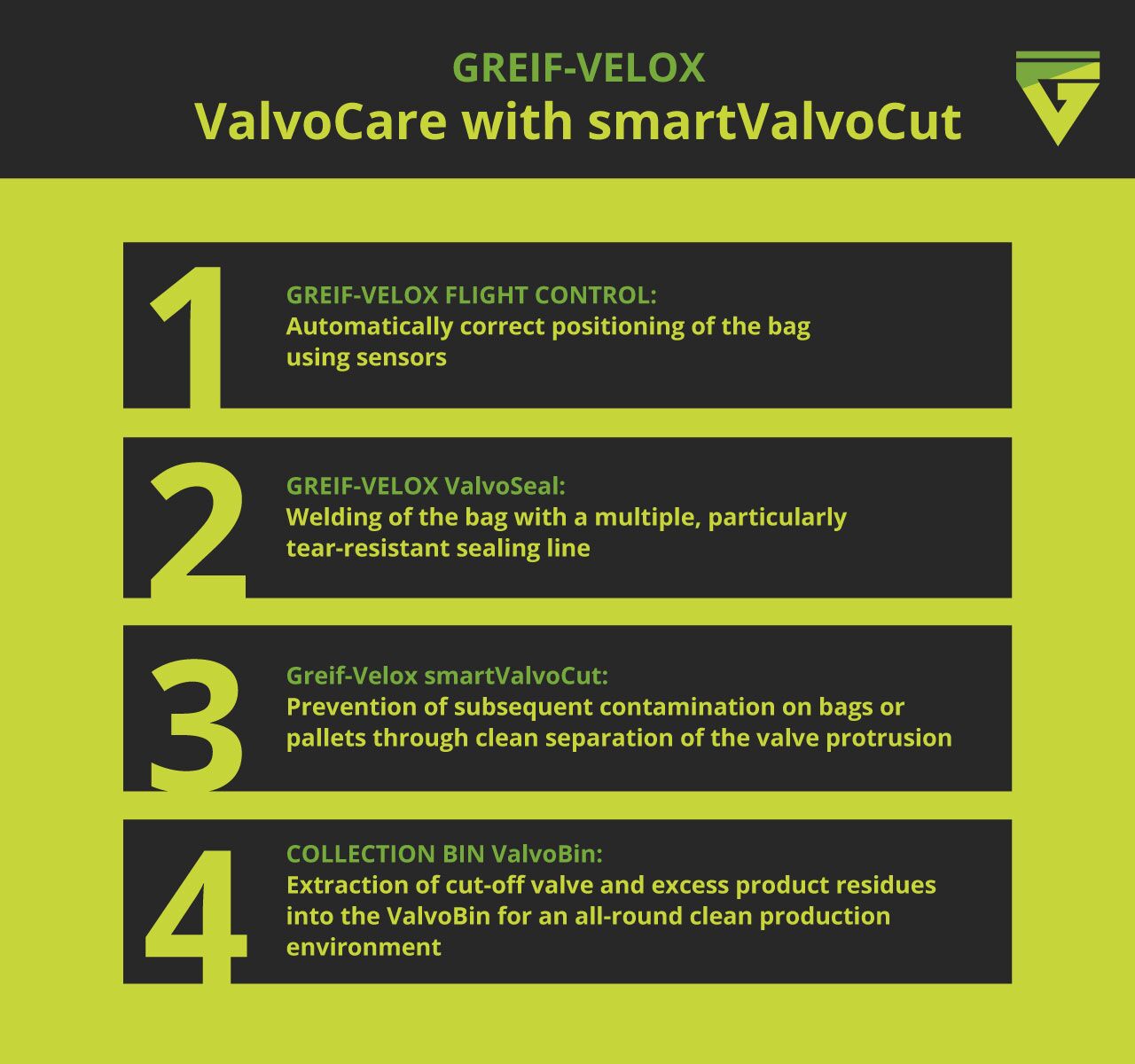

Greif-Velox combines all these features in the new ValvoCare station:

1. gripper Velox Flight Control: Once the filled, still open bag has been moved towards the ValvoCare station, sensors ensure that the bag is automatically positioned correctly. This creates a process that is 100% reliable and eliminates the need to change the presettings that are often necessary after a bag change.

2. Greif-Velox ValvoSeal: The patented ultrasonic sealing unit is currently the strongest on the market: It seals the bag with a multiple, particularly tear-resistant sealing line up to 60% stronger than all other solutions available on the market. Thanks to the multiple sealing line, closure is possible even if there is product on the sealing line during the sealing process. This is especially true for the particularly critical edges of the valve.

3. gripper Velox smartValvoCut: As product residue often remains between the open end of the valve and the seal seam, the excess valve is removed directly after the sealing process. Subsequent contamination on bags or pallets is prevented by a blade behind the sonotrode that cleanly cuts off the valve residue. The dust residue is then removed by a blower.

4. The ValvoBin collection bin enables an all-round clean production environment. The cut-off valve residues, including the excess product, are sucked into the ValvoBin and can be disposed of at the end of the shift.

The VeloVac system can also be supplemented with the patented Greif-Velox ValvoDetect optical measuring system. It checks whether the bag valve is positioned at the correct angle to the sealing sonotrodes to ensure correct sealing. In this way, incorrectly processed and incorrectly positioned bags can be detected in advance and sorted out before they cause consequential costs due to contamination.

To ensure consistently high machine availability without unplanned downtimes, the blade of the smartValvoCut is equipped with an RFID tag and an automatic service message: The gripper Velox smartBlade informs users when the blade needs to be replaced or refurbished. The pressure and speed of the cutting process are also evaluated in order to maximize the service life of the blade, detect possible wear, optimize parameters or replace the blade. Two different models are available for knife replacement: New or refurbished knives can be ordered from Greif-Velox or the system can initiate an automatic reorder from the manufacturer based on previously defined parameters.