Proven technology, quickly available for you - the new Essential Line

„With the Essential Line, we are creating a new entry-level class that offers our customers maximum planning reliability, quality and speed - ideal for anyone who wants to organize their production economically and efficiently.“

Sebastian Pohl, Managing Director GREIF-VELOX

R-DOS Essential

Compact. Stable. Easy to integrate: The R-DOS Essential is the economical solution for the precise filling of liquid substances into canisters, drums and IBCs. The liquid filling system covers around 80 % of typical applications and is optimized for fast availability and minimal training and maintenance requirements.

Viscosity range: 1 to 1,500 mPas

Semi-automatic under mirror operation

Filling capacity: up to 42,200 l drums/h or 13 IBC/h

Operation via an intuitive panel

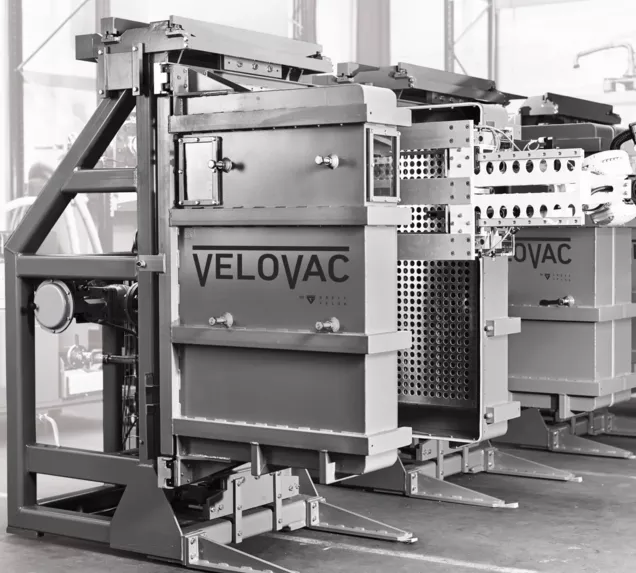

VeloVac Essential

The VeloVac Essential was developed for dust-free bagging of ultra-light powders such as carbon black or silica. It uses proven vacuum technology and is available in a standardized version - with reduced design effort, short lead times and modular expandability. Ideal for companies that want to combine maximum tightness, low transport volume and reduced operating costs.

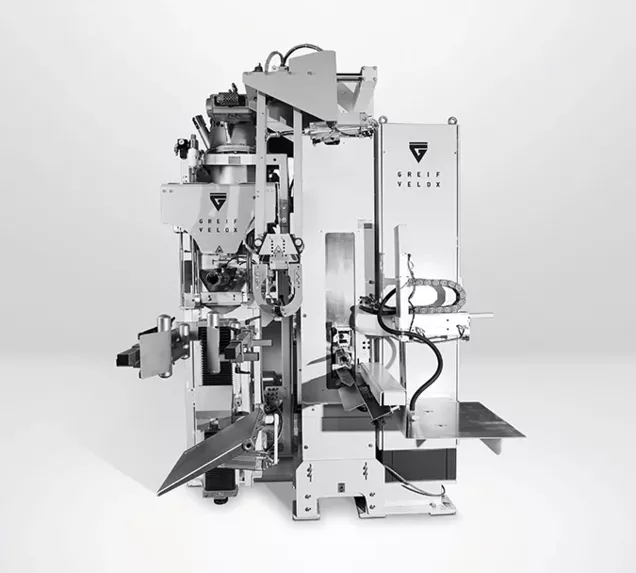

BVP Essential

The BVP Essential is a pneumatic gross packer for bagging bulk goods in paper bags or woven plastic bags. The system has been consistently designed for standardization: robust construction, compact design, quick changeover. Particularly suitable for companies with clear process requirements and the desire for minimum integration time.

Find the right contact person

Direct contact to GREIF-VELOX or competent trading partner at your location:

You will find the right contact person for your request here.

This is GREIF-VELOX: a pioneer of filling and packaging technology in 1,000 years of company history

EIR - Efficiency, innovation, reliability

are the cornerstones of our business philosophy

Reduction of operating costs

by reducing transport and logistics costs & saving cleaning and personnel costs

Optimization of production processes

by reducing downtimes, increasing production performance and data-supported process optimization

Improve security and compliance

by increasing employee and product safety

Innovation leadership in the filling and packaging industry

by integrating real-time data collection and Industry 4.0 concepts

Development of customer-specific solutions

through tailor-made adjustments based on specific customer needs, resulting in more efficient production processes

Promoting digital transformation

by using the latest digital tools and platforms for optimized and transparent production, increases productivity and reduces downtime

Maximum system availability

through robust design principles and continuous quality controls, resulting in lower failure rates and longer life cycles of the systems

Competent customer support

through rapid technical support & comprehensive maintenance programs, resulting in minimized downtime and optimized operations

Comprehensive security standards

through ongoing training and safety checks, ensures maximum safety for personnel and production