Bagging revolution: Filling ultra-light powders safely and cleanly in FIBCs

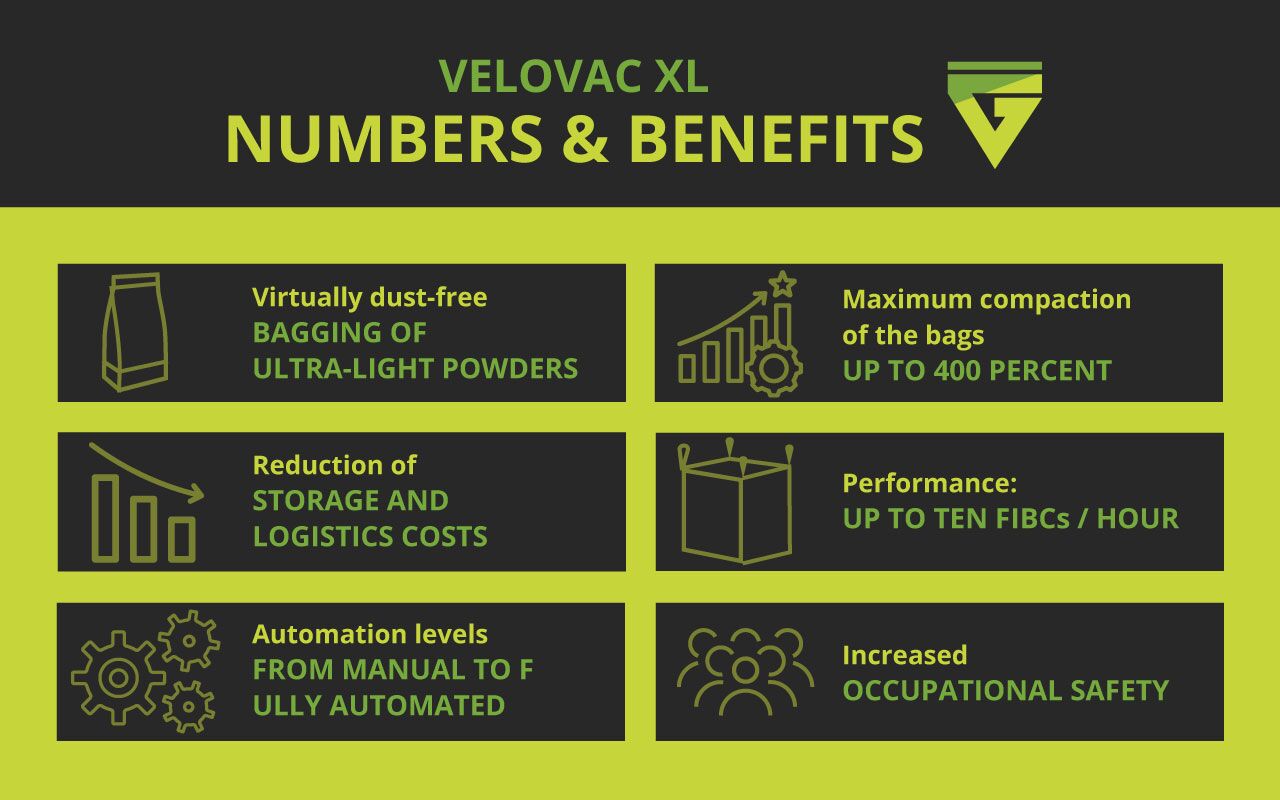

Until now, ultra-light powders such as carbon black or fumed silica were particularly difficult to bag safely and compactly in FIBCs ("BigBags") due to their nature. Maschinenfabrik Greif-Velox now offers a unique solution with the vacuum technology of the VeloVac XL: It ensures clean, fast and compact bagging, which minimizes logistics and transport costs as well as product loss and increases occupational safety. At the same time, the use of larger containers ensures economic and ecological benefits.

The VeloVac-XL vacuum system from Greif-Velox offers virtually dust-free and compact bagging of ultra-light powders thanks to an innovative technology: powders with particle sizes of less than 200 micrometers and a bulk density of 10 to 450 grams per liter are filled in a completely closed vacuum chamber. In contrast to pump packer systems, an atmospheric vacuum is generated in this chamber, which draws the product directly into the FIBC without any losses. Any dust that escapes is automatically extracted and fed directly back into the bagging process.

Increased occupational safety, reduction of storage and logistics costs

This particularly low-dust and clean bagging saves users high costs for the often very time-consuming cleaning of the system environment. At the same time, employees are effectively protected from toxic or carcinogenic dust. The up to 400% compaction of the bags compared to conventional pump packer systems saves three quarters of the costs for storage and logistics.

Cost and time savings thanks to high performance

Time and costs can also be minimized by using FIBCs: Compared to bagging in 7.5-kilogram valve bags, users can fill up to 66 times the quantity into an FIBC at once with the Greif VeloVac XL. This also makes handling easier and more efficient for end customers: Larger bags can be processed and emptied more quickly; in addition, the cost savings for packaging material are up to 30 percent. The VeloVac XL is also characterized by its high performance: Four to ten FIBCs can be filled per hour, depending on the structure of the product feed and the product properties - in all desired bag sizes with a filling weight of up to 500 kilograms.

Automation levels of the VeloVac XL: from manual to fully automated

The modular VeloVac XL design is also flexible depending on customer requirements: various automation levels are available. In the first, manual level, the chamber can be reached via a mobile lifting platform; the highest automation level as a full line guarantees fully automatic handling. Only the hanging and closing of the FIBC needs to be carried out by an operator, so that less than a third of an FTE (full-time equivalent) is required for the same output quantity compared to the manual version.

Driving force for the expansion of electromobility and renewable energies

The particularly efficient bagging of ultra-light powders by the VeloVac XL from Greif-Velox is also driving two important future industries forward: electromobility and the renewable energy sector. This is because high-quality carbon black is an important component of lithium-ion batteries and other electricity storage applications. Pyrogenic silicon dioxide, also known as fumed silica, is an important material for the construction and expansion of high-performance wind turbines, for example.