Customised system components for silica

The „Clean Cycle of Packaging”

Product: Specially developed paper valve bags guarantee optimum air circulation and product protection, even with bulk densities below 50 g/l.

Packaging: In close cooperation with LC Packaging, a system is being realised that takes the individual physical properties of silica precisely into account.

System: The closed vacuum process not only minimises dust emissions, but also ensures continuously high compaction - ideal for a smooth production process.

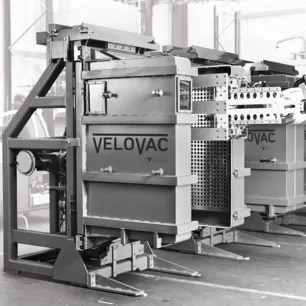

VeloVac Vacuum packer: Innovation for silica filling

The VeloVac was specially developed to meet the challenges of ultra-fine silica. The fully enclosed vacuum chamber ensures a dust-free process, while the integrated vacuum pump and CIP (Clean in Place) function significantly reduce both energy and cleaning costs.

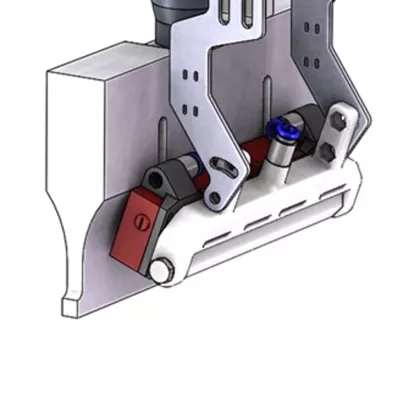

Technical advantages of silica filling

Optimised compaction: Precise suction means that silica is packed so compactly that transport volumes and storage costs are significantly reduced

Safety standards: Automated process control eliminates manual intervention and thus reduces the risk of harmful dust exposure

Process stability: Continuous monitoring and adjustment of the vacuum parameters ensures an uninterrupted production process

Flexible system options

Automated material handling: Robot-supported systems take over the precise feeding and handling of the bags

Customised system configuration: Adaptable modules enable use with varying production volumes and material properties

Advanced safety features: Integrated sensors and real-time monitoring guarantee maximum process reliability and quality

Kompatible Features

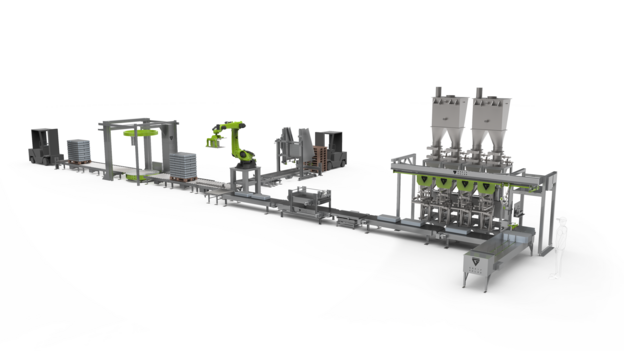

Interactive 3D animation of a VeloVac full-line system

Experience and explore in 3D

It's worth the wait: After the 3D animation is loaded, you can use it with the mouse pointer and mouse wheel (zoom). Don't miss to click on the -buttons.

Holistic system solutions through full-line filling systems

Our filling systems are part of a comprehensive production system that can be seamlessly integrated into existing lines. GREIF-VELOX ensures that each system is optimally tailored to the specific requirements of customers in order to maximize productivity and reduce operating costs.

Find the right contact person

Direct contact to GREIF-VELOX or competent trading partner at your location:

You will find the right contact person for your request here.