Specialised system components for crop protection products

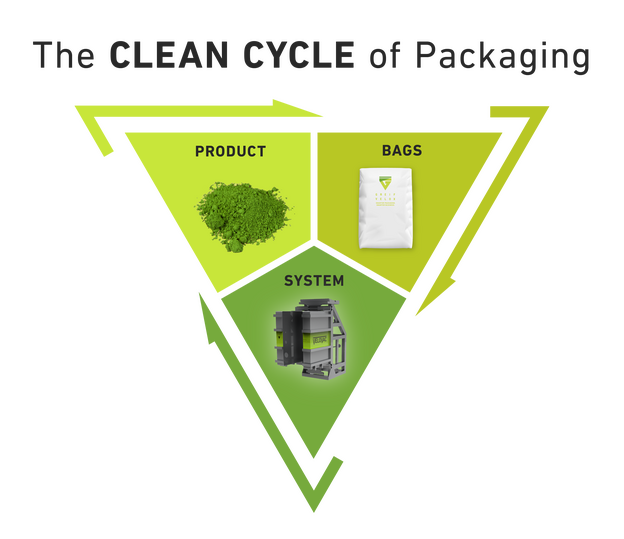

The „Clean Cycle of Packaging”

Product: Specially developed paper bags guarantee a tight seal and prevent harmful substances from escaping even under extreme conditions.

Packaging: In collaboration with experienced partners, a packaging system is realised that precisely maps all relevant safety and leak-tightness requirements.

System: The fully enclosed vacuum process not only reduces hazardous dust emissions, but also enables homogeneous compaction of the material - essential for compliance with strict environmental and safety standards.

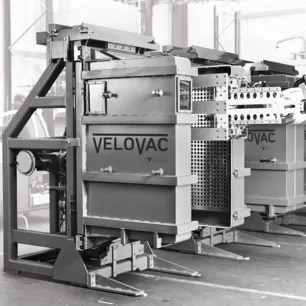

VeloVac Vacuum packer: The best filling solution for crop protection products

Specially designed for bagging toxic powders, the VeloVac utilises a completely closed process that protects both the environment and the health of employees.

Technical advantages for the bagging of crop protection products

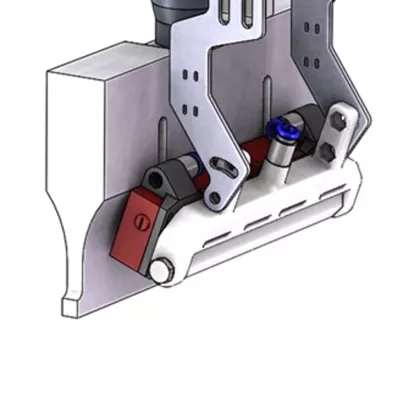

Maximum tightness: Thanks to the integrated ValvoSeal unit, an absolutely secure bag closure is guaranteed - ideal for transporting hazardous substances

Reduction of health risks: Automated, closed processes prevent any release of toxic particles

Efficient logistics: Maximum compaction reduces transport volumes, which leads directly to cost savings in storage and transport

Energy and resource efficiency: The innovative vacuum pump saves up to 30 % energy, which also reduces operating costs

Flexible options and system variants

Automated handling: Robotic solutions take over the precise filling and handling of the bags, minimising manual risks

Modular system configuration: The systems can be flexibly adapted to different production volumes and specific crop protection product requirements

Advanced process monitoring: Real-time data acquisition and sensor technology guarantee consistently safe and reliable operation

Kompatible Features

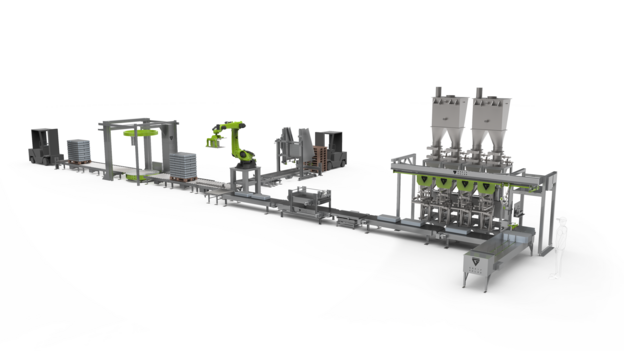

Interactive 3D animation of a VeloVac full-line system

Experience and explore in 3D

It's worth the wait: After the 3D animation is loaded, you can use it with the mouse pointer and mouse wheel (zoom). Don't miss to click on the -buttons.

Holistic system solutions through full-line filling systems

Our filling systems are part of a comprehensive production system that can be seamlessly integrated into existing lines. GREIF-VELOX ensures that each system is optimally tailored to the specific requirements of customers in order to maximize productivity and reduce operating costs.

Find the right contact person

Direct contact to GREIF-VELOX or competent trading partner at your location:

You will find the right contact person for your request here.