Optimised components for pigment filling

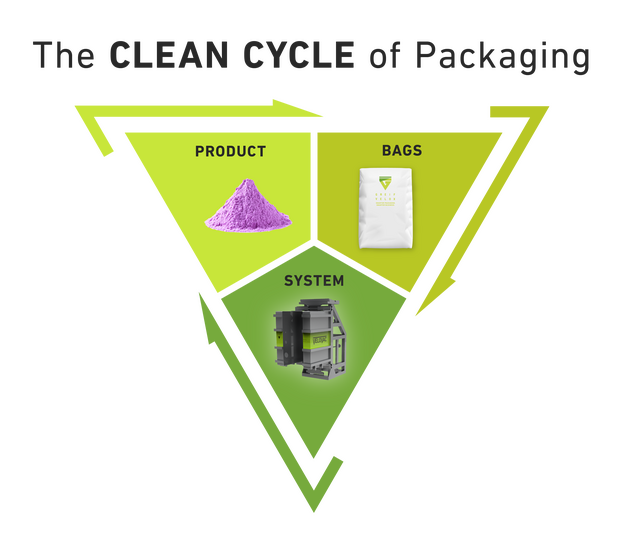

The „Clean Cycle of Packaging”

Product: Highly specialised paper sacks offer precisely coordinated ventilation and sealing so that even pigments with sensitive properties are optimally packaged.

Packaging: Together with partners from the pigment industry, a system is being developed that precisely fulfils specific requirements - from particle size to chemical stability.

System: The fully integrated vacuum process not only reduces dust emissions, but also optimises the density and stability of the end product.

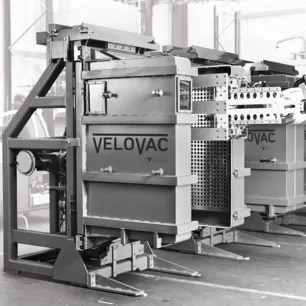

VeloVac Vacuum packer: Customised solution for pigments

The VeloVac was designed for the precise bagging of finely dispersed colour pigments. The fully enclosed vacuum chamber ensures that no disruptive dust clouds are created and the material density is constantly optimised.

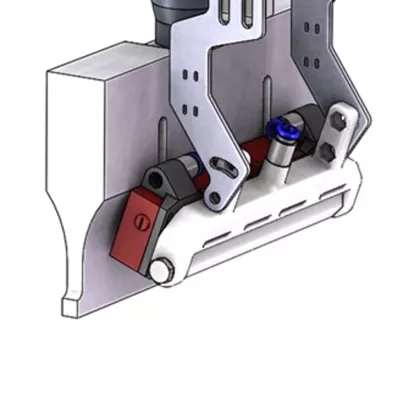

Technical advantages in pigment filling

Maximum compaction: Achieved through controlled vacuum processes, the technology drastically reduces the amount of material required in the warehouse

Process reliability: Automated control minimises manual intervention and thus guarantees consistently high product quality

Reduction in downtime: The stable and closed system significantly reduces maintenance and cleaning intervals

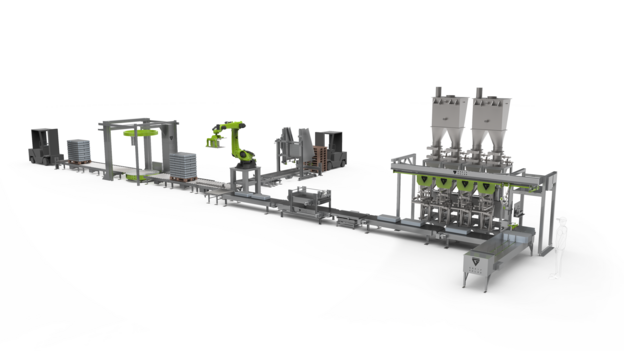

System variants and configuration options

Robot-assisted material handling: For precise filling and handling of the bags

Flexible system configuration: Customisable modules enable a smooth transition between different pigment types and production quantities

Integrated process monitoring: Real-time sensors and control systems ensure the highest quality standards throughout the entire production process

Kompatible Features

Interactive 3D animation of a VeloVac full-line system

Experience and explore in 3D

It's worth the wait: After the 3D animation is loaded, you can use it with the mouse pointer and mouse wheel (zoom). Don't miss to click on the -buttons.

Holistic system solutions through full-line filling systems

Our filling systems are part of a comprehensive production system that can be seamlessly integrated into existing lines. GREIF-VELOX ensures that each system is optimally tailored to the specific requirements of customers in order to maximize productivity and reduce operating costs.

Find the right contact person

Direct contact to GREIF-VELOX or competent trading partner at your location:

You will find the right contact person for your request here.