Who is dy-pack?

dy-pack has been developing and producing specialized valve bags for the chemical, construction and food industries for over 50 years. The company is known for innovative packaging technologies that provide an optimal moisture barrier and special venting techniques. dy-pack uses sustainable materials such as recyclable plastic and relies on energy-efficient production processes to minimize environmental impact. This means that dy-pack also meets GREIF-VELOX's key success drivers for innovative production technology.

The 6 Key Success Drivers from GREIF-VELOX

For innovative production technology

Sustainability

Sustainability at GREIF-VELOX means a significant reduction in the CO₂ footprint through the use of energy-efficient and waste-minimizing technologies that not only protect the environment, but also reduce operating costs.

Quality

Quality at GREIF-VELOX means compliance with the highest industry standards and customer expectations through precise processing and control, which leads to increased customer satisfaction.

Performance

Performance reflects our commitment to delivering powerful and reliable systems that increase productivity and ensure consistently high output levels.

Availability

Availability underlines our commitment to maximum asset availability and minimal downtime, supported by proactive maintenance and rapid customer service, resulting in optimized uptime.

Efficiency

Efficiency is embodied by our filling solutions, which streamline production processes, minimize resource consumption and thus help reduce costs without compromising product quality.

Cleanliness

Cleanliness in our context means adhering to the strictest hygiene standards to ensure the safety and purity of products in chemical, petrochemical and food industries, minimizing the risk of contamination.

What is SAFEDyVac?

The advanced packaging system

SAFEDyVac is an advanced packaging system developed by us in collaboration with dy-pack to package ultrafine powders safely and efficiently. There are three specific product variants, each tailored to different filling or packaging requirements and material properties:

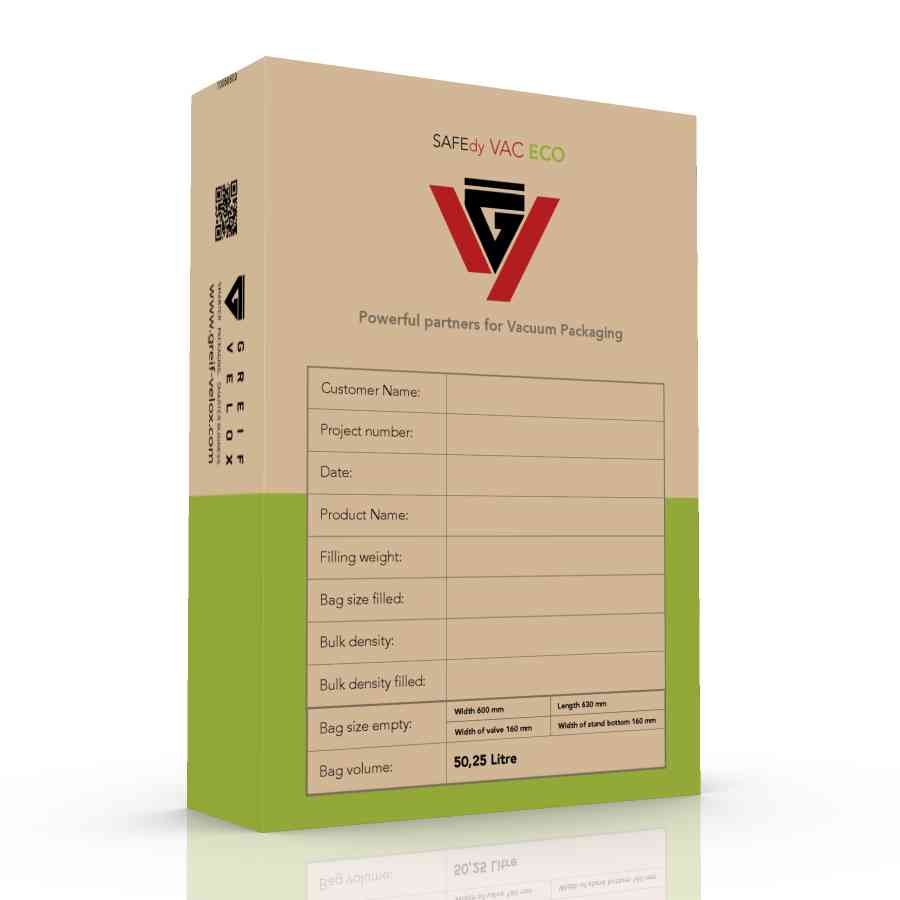

SAFEDyVac ECO

This variant is particularly suitable for production companies that require a sustainable and fully recyclable packaging solution.

Product features

SAFEDyVac ECO uses environmentally friendly materials and is designed to reduce the ecological footprint. It offers optimal protection against moisture and at the same time guarantees dust-free packaging.

Application

Ideal for filling or bagging where environmental aspects are a priority and a high level of recyclability of the packaging materials is desired.

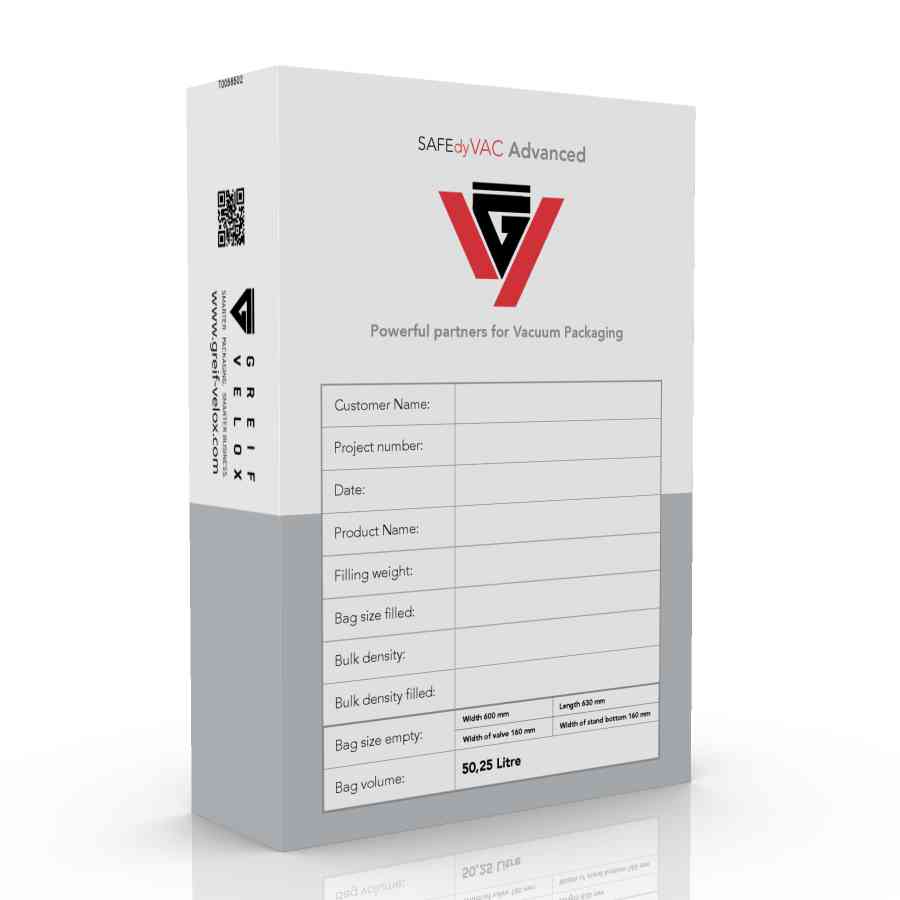

SAFEDyVac Advanced

SAFEDyVac Advanced is designed for production facilities that require both high product protection and high performance requirements.

Product features

SAFEDyVac Advanced offers excellent venting during the packaging process and ensures efficient and safe packaging. It combines a strong moisture barrier with high mechanical strength.

Application

Particularly suitable for industrial applications where both protection and efficiency are crucial, such as in the chemical industry or construction chemicals.

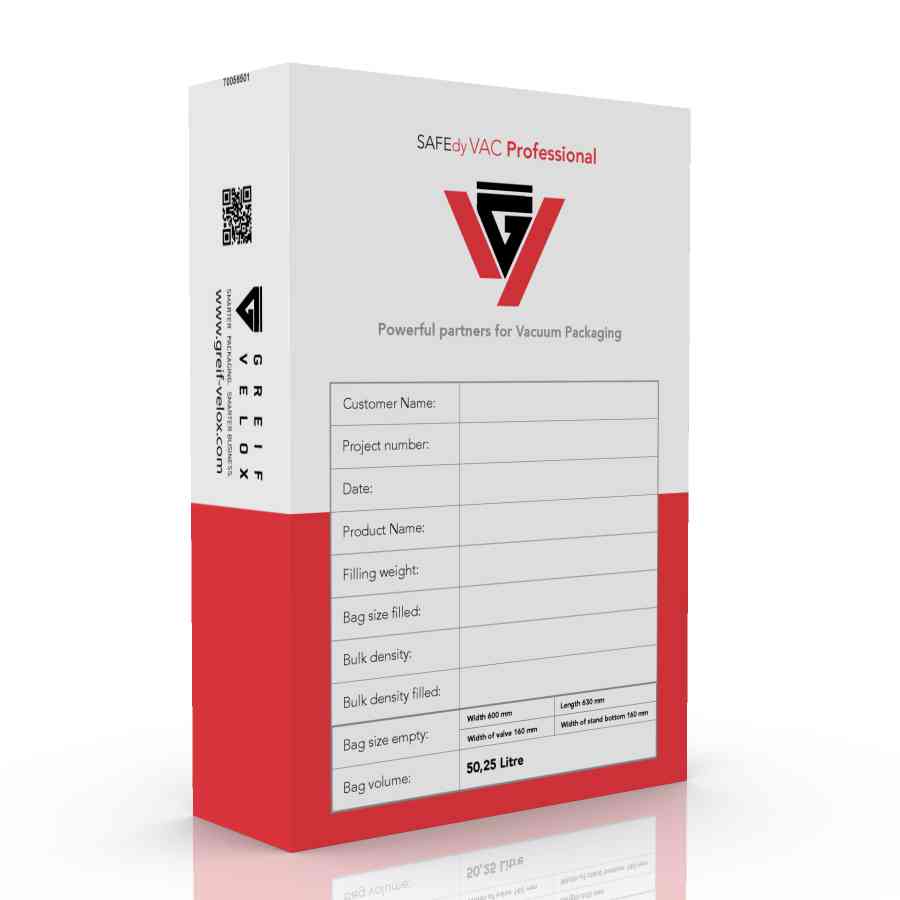

SAFEDyVac Professional

SAFEDyVac Professional has been specially developed for the high demands of battery manufacturing, especially for the bagging of lamp black.

Product features

SAFEDyVac Professional offers optimal moisture protection and a special venting technology that ensures that the product remains dry during the packaging process and does not absorb moisture.

Application

Ideal for battery manufacturing and other filling and packaging processes where extreme cleanliness and protection requirements exist.

| Product | ECO | Advanced | Professional |

|---|---|---|---|

| Moisture protection | |||

| Dust-free | |||

| Suitable for use in manual and automatic systems | |||

| Sustainability | |||

| Bag thickness | |||

| Excellent packing shape | |||

| Filling capacity | |||

| Food-safe | |||

| Suitable for hazardous substances |

For over 60 years, GREIF-VELOX has been firmly established in the international markets of the chemical, food and petrochemical industries and is valued by customers and partners for its tailor-made filling and packaging solutions, reliability and innovative strength.

Quote: Managing Director Sebastian Pohl

Ideal bagging results through perfect coordination

In this partnership, we can not only develop bags that are tailored to the system, but also tailor our systems perfectly to the packaging. There has never been anything like this before.

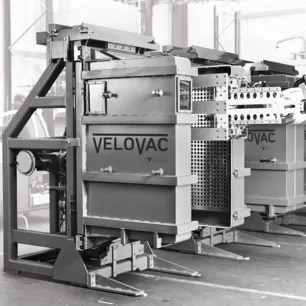

SAFEDyVac in use when filling light powders with the VeloVac

VeloVac vacuum packer: Revolution in the bagging of carbon black

The VeloVac has been specially developed for the challenges of carbon black bagging. By using a completely enclosed vacuum chamber, the fine powder is packed safely and without dust emissions.

Advantages of carbon black bagging with the VeloVac

Reduced cleaning costs: Completely closed system prevents dust emissions

Health protection: No exposure of employees to fine carbon black

Optimized logistics: Fourfold compaction of the material saves costs and space during transport and storage

Higher product purity: Important requirement for applications such as battery production

Options for the Carbon black bagging

Automated handling: Robot systems for handling the filled bags

Customizable configuration: Flexible adaptation of the system to specific customer needs and production volumes

Extended safety features: Integrated monitoring systems to ensure plant and production process safety

Find the right contact person

Direct contact to GREIF-VELOX or competent trading partner at your location:

You will find the right contact person for your request here.