Case studies for increasing efficiency and flexibility with GREIF-VELOX machines

Through innovative engineering solutions for more precise, faster and safer machines

We demonstrate how GREIF-VELOX uses individually tailored filling, bagging and packaging machines to improve production speed, measurement accuracy and operational safety in specific production facilities worldwide. Our detailed case studies illustrate diverse success stories in the chemical, food and other sectors, supported by quantitative results and real improvements.

Chemical and food industry

Innovative solids bagging machine for ICL Ladenburg

The solid bagging machine from GREIF-VELOX at ICL Ladenburg led to a significant reduction in complaint and cleaning costs, which were originally caused by incorrectly welded bags. This cost problem, which amounted to at least 20,000 euros annually, was radically improved by the introduction of the ValvoDetect on the BVP air packer. With its optical sensors, ValvoDetect ensures that only correctly positioned bags are welded by detecting and sorting out incorrectly attached bags before welding.

Chemical industry

Hydrogen peroxide filling machine for Evonik

Our filling machine at the chemical company Evonik led to an impressive increase in filling speed by 50 percent. Additionally, we significantly improved product safety by implementing advanced contamination control measures integrated into a highly automated hydrogen peroxide filling machine, increasing not only efficiency but also workplace safety.

Food industry

Bagging machine for GoodMills Germany

At the food producer GoodMills Germany, we were able to significantly increase packaging efficiency by 100 percent thanks to our machines. We also maximized the accuracy of the bagging processes, doubling production output to up to 400 bags per hour, while at the same time minimizing cleaning effort and changeover times by using our gross pneumatic packer BVPV 4.40.

Food industry

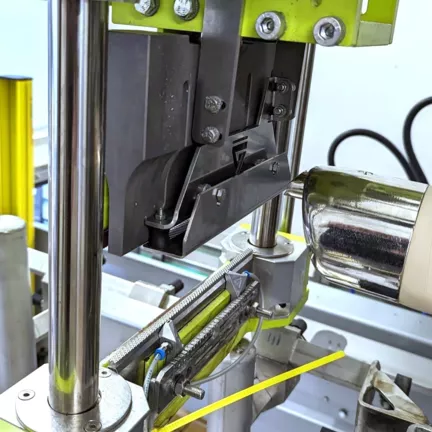

Bagging system for Omnisal

The new full-line bagging system with the Greif-Velox BVPV 4.40 high-speed air packer optimises the bagging of phosphate mixtures at Omnisal. With a hygienic design made of stainless steel, a fully automated complete bagging system including precise robotics and conveyor technology as well as an optical measuring system (ValvoDetect) and an ultrasonic sealing unit (ValvoSeal), complaint and cleaning costs are significantly reduced. The system integrates seamlessly into existing production processes, minimises downtimes during product changeovers and guarantees maximum process and product safety.

Chemical industry

Efficient wax bagging machine for Reagens Deutschland GmbH

At Reagens Deutschland in Loxstedt, the GREIF-VELOX air packer BVP has drastically reduced cleaning and downtimes when bagging micronized waxes and wax mixtures. Thanks to the innovative residual emptying function with optimized bowl shape and air purging system, the cleaning time for product changes has been reduced by 80 percent - from 30 minutes to just 5 minutes. At the same time, less than 12 grams of product remain in the bowl, which means that product losses can be almost completely avoided and the efficiency of the entire bagging process is significantly increased.

Factory Acceptance Tests (FAT)

Successful handover and installation of GREIF-VELOX systems for customers

Further practical examples of successful factory commissioning of our systems in our customers' production lines are shown in our Factory Acceptance Tests (FAT).