Bagging of Light Materials and Solids

GREIF-VELOX bagging machines deliver innovative solutions for precise dosing and secure packaging of manageable materials.

Our machines are engineered to process even light, dust-prone materials—from coarse granules to fine powders and lightweight substances—minimizing product loss while upholding the highest safety standards.

further information about bagging machinesManageable Materials

Coarse Materials & Granules: Chemicals, waxes, titanium dioxide, phosphates, cocoa, starch, sugar, and more

Fine Powders & Lightweight Substances: Carbon black, silica, pigment powders, plant protection products, and more

Technological Advantages

Precision Dosing: Advanced dosing technology ensures consistent fill volumes and minimizes product loss

Versatile Material Handling: Engineered to process a wide range of materials—from coarse granules to fine powders and lightweight substances—ensuring optimal performance across various applications

Enhanced Dust Control & Safety: Integrated machines effectively manage dust and airborne particles, maintaining a clean environment and meeting strict safety standards

Robust and Durable Design: Constructed with high-quality materials to deliver reliable performance in demanding industrial settings

Seamless Integration & Automation: Easily incorporated into existing production lines, our fully automated machines boost efficiency and streamline operations

Liquid Filling

GREIF-VELOX offers specialized machines for the precise, automated, and secure filling of liquids.

Our filling machines are engineered to achieve maximum dosing accuracy while minimizing product loss—using technologies developed exclusively for liquid filling applications.

Every filling machine is tailored to the specific production conditions and objectives of our clients, ensuring peak efficiency and machine performance.

further information about filling machinesManageable Liquids

Handling liquids of varying viscosities—from water to thicker oils and syrups.

Technological Advantages

Precise Dosing: Optimal control of fill volumes ensures consistent quality and minimal product loss

Versatile Container Adaptability: Designed to fill canisters, drums, and Intermediate Bulk Containers (IBC) to meet diverse requirements

Adaptability to Liquid Properties: Suitable for liquids ranging from watery to highly viscous consistencies

Specialized Filling Technologies: Incorporates bottom-fill, top-fill, and under-chamber fill machines to meet specific process requirements optimally

Integrated Safety and Automation Machines: Ensure smooth production operations and reduce operator errors

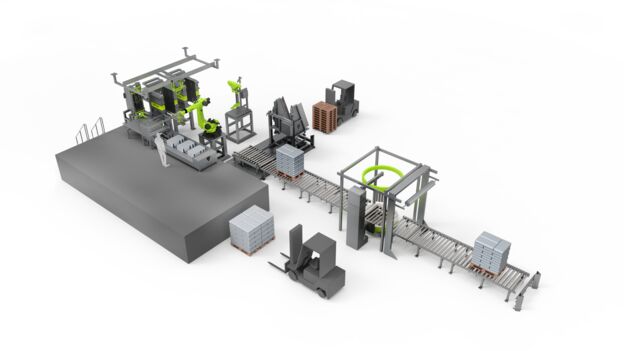

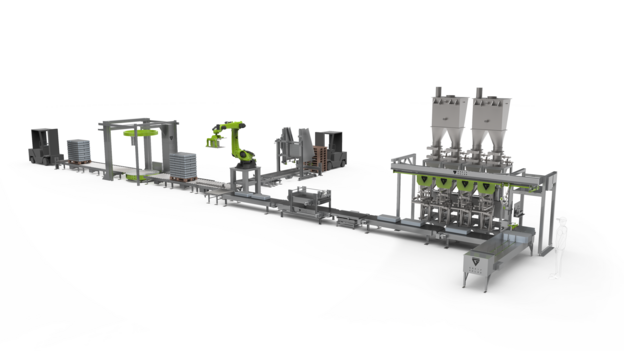

Palletizing robot

GREIF-VELOX improves efficiency throughout the entire production chain for industries such as food and chemicals with advanced palletizing robots. These robots provide precise and fast palletizing and help optimize bag attachment, bag handling and final packaging.

The adaptability of our robots allows us to handle a wide variety of product shapes and packaging types, allowing a flexible response to different production requirements.

The configuration of each machine is tailor-made according to the individual requirements of the customers, which optimizes production processes and improves working conditions.

further information about palletizing robots

Technological advantages

Increased production speed and accuracy.

Use of innovative gripping machines and advanced motion control techniques for fast and accurate palletizing.

Flexibility and adaptability.

Modular machine configuration enables easy adjustments to new product types and packaging formats.

Improving work safety and ergonomics.

Automation reduces manual handling processes, which lowers the risk of injury. You can also counter the shortage of skilled workers.

Longevity and reduced maintenance.

The robust construction and the use of high-quality materials ensure a longer service life of the machines and reduce maintenance costs.